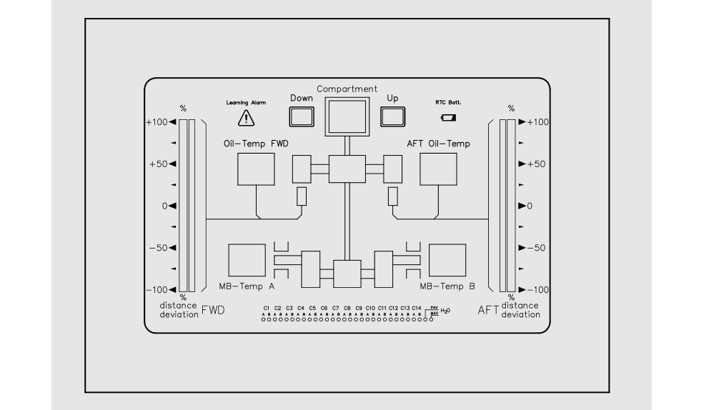

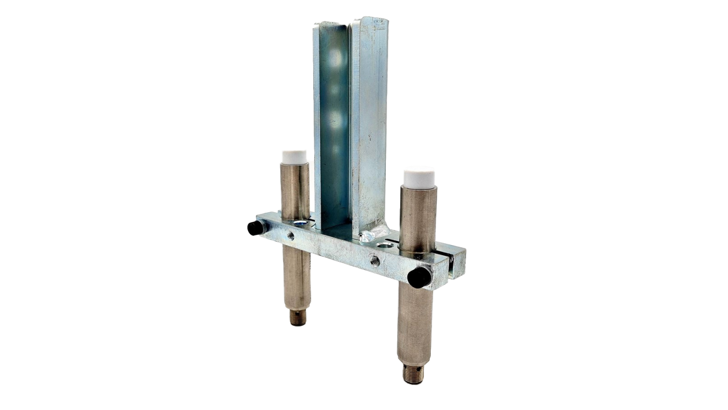

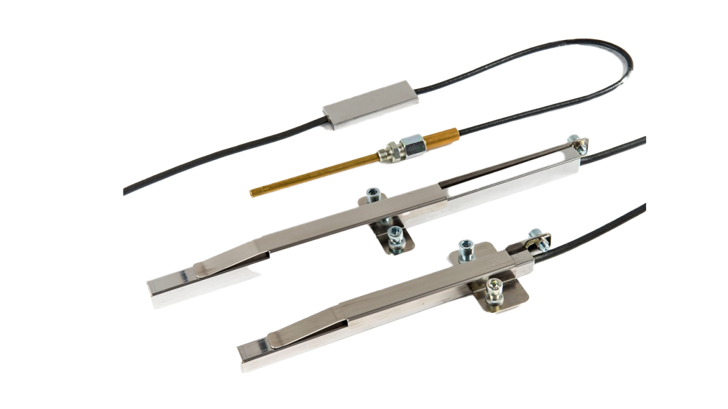

Empty Bearing Distance Monitoring System

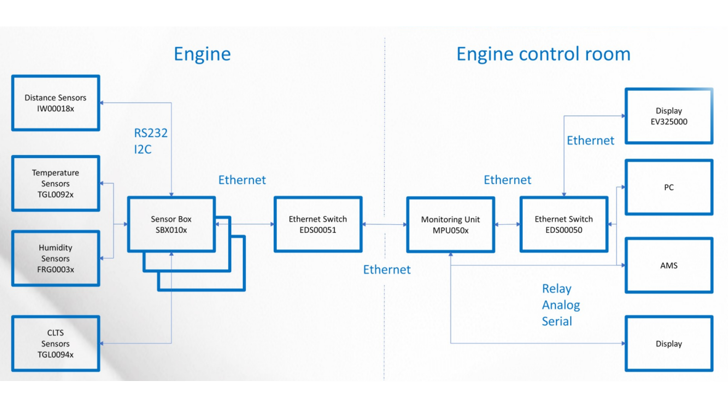

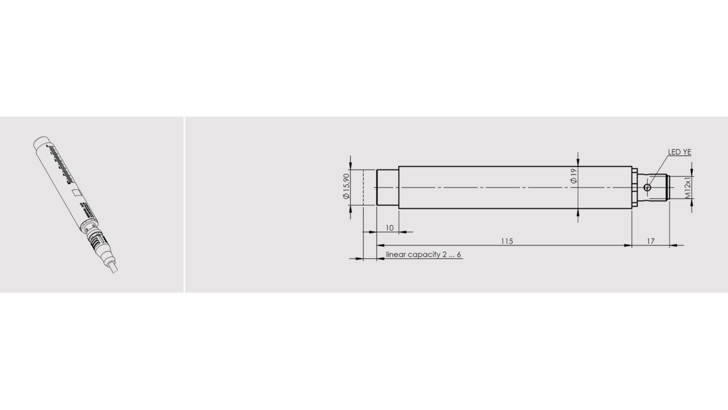

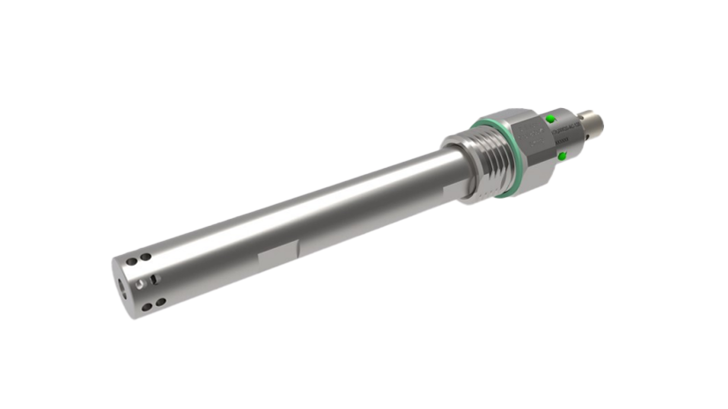

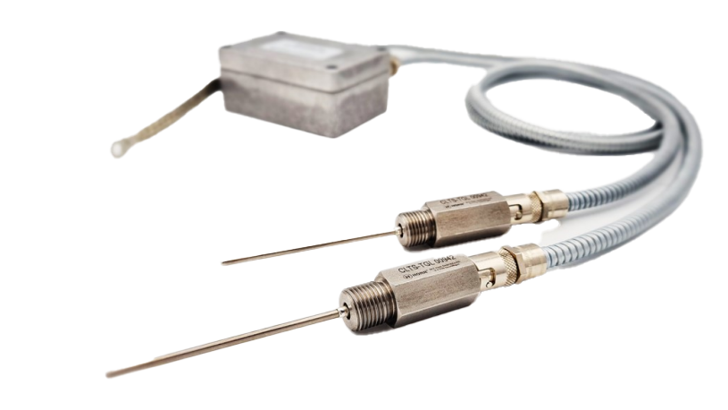

The Bearing Monitoring System from HORN makes continuous surveillance of your engine in relation to the distance between the sensor and the cross hear in its lower dead point position, which is a measure of the bearing wear.

One of the key benefits of the 2-stroke bearing monitoring system is improved reliability. By detecting potential issues early, operators can take proactive measures to prevent failures and minimize downtime. This can help to increase the overall lifespan of the engine and reduce the need for costly repairs.

Moreover, the system benefits you because of the:

- Fully controlled bearing status

- Up to 72 sensors in different locations for thermal and distance sensing

- Integrated water in oil sensing system

- Trend displays for long-term information

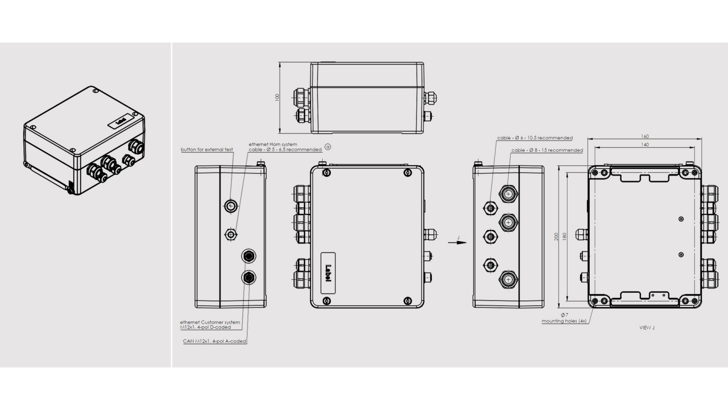

- Retrofit solution available.

For sales or commercial inquiries please contact us at marine@insatech.com.