Measuring flow might be the primary measurement required to get an insight into the operation and engine performance. Whether it is fuel consumption, lube oil supply, potable water usage or cargo transfer, using an accurate flow meter for the process will allow better control and reliable data for future improvement of processes. Coriolis Mass Flow Meters are mainly known for its use in bunker transfers, but the capabilities of these highly trustworthy instruments.

Flow Switch - Water & Oil

Flow Captor 432x.8xM/xx

The flow-captor 432x.8xM/xx from Weber Sensors is a inline flow switch for water and oil based media in stainless steel housing with relay output (90 - 250 VDC). Pipe sizes: from 8 - 28 mm OD.

Flow Switch - Water & Oil

Flow Captor 442x.1xM/xx

The flow-captor 442x.1xM/xx from Weber Sensors is a inline flow switch for water based media in stainless steel housing with transistor output and PT100 temperature measuring element. Pipe sizes: from 6 - 28 mm OD

Flow Switch - Water & Oil

Flow Captor 4320/xx + 402x.1x S200

Inline flow switch for water-based media (remote system). Also available in a high-temperature version suitable for medium temperatures up to 135 °C / 275 °F (S202). Pipe diameters: 6 - 28 mm OD

Flow meter - Water

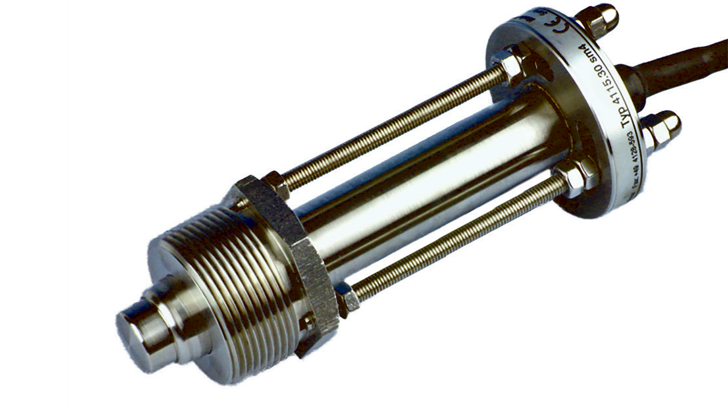

Flow Captor 4114.30

Flow meter for water based media in a rugged stainless steel version (full encapsulation). Diameter 1¼" / 32 mm.

Flow meter - Water

Flow Captor 4115.3x

Flow meter for water based media in a rugged stainless steel version (full encapsulation). Diameter 1" / 25 mm.

Flow meter - Oil

Flow Captor 4115.3x S115

Flow meter for oil based media in a rugged stainless steel version (full encapsulation). Diameter 1" / 25 mm.

Flow meter - Water

Flow Captor 4215.3x

Flow meter for water based media in a rugged stainless steel version (full encapsulation) with additional temperature output. Diameter 1" / 25 mm.

Flow meter - Water

Flow Captor 4115 S101 + 4015.3x S101

Flow meter for water based media (remote electronic and sensor) in a rugged industrial design (special potting of sensor head and electronics). Medium temperatur up to 135 °C

No results found

Flowmeters

Flow Basics

In order to use or add something to a process, you will have to move it and by moving it, a flow will be generated. This is universal, and regardless of what is being consumed or added to a process,

a flow is inevitable as flow is an indication of movement. As a consequence, if you wish to measure what is being consumed it is often the easiest to measure the flow of supply.

Depending on which flow you want to measure, in which application and under what conditions, different types of principles can be used, their common denominator is that they are flow meters. Each type of flow meter has its own benefits and disadvantages, to choosing the correct flow meter is quite important – in the worst case you could end up with a flow meter that does not measure correctly or not as expected, which can potentially affect your production or process negatively.

An Endless Flow of Possibilities

Using the correct flow meter for your application can greatly enhance the productivity of your operations. In some cases, a general indication of the flow might be sufficient for the process, and in others high accuracy can greatly improve efficiency. By using high accuracy flow meters in a production or operation, you can gain insights into the effects of even minor changes in behavior or routines – this is especially true on board ships. Imagine being able to see the impact of your efforts from maintenance of main components, implementing new tech or even changes in crew behavior, in the fuel you consume – this is actually possible with the right flow meter in the right place.

We Will Gladly Guide Your Flow Measurements

We have been supplying most flow meter types for decades, and we know which type of instrument would be best suited for your application. We will gladly assist you in choosing the correct flow meter and whether you focus on accuracy, special ambient conditions, ease of installation or price, we aim to provide you with the right solution the first time. As we have all supporting functions in-house, we can even help you with installation, maintenance, repair or up-stream signal integration.