Being able to control flow, flow rates and flow direction, is critical to many processes. Depending on process flow, pressure and media, different types of valves need to be utilized. Ball valves, needle valves, solenoid valves, butterfly valves and pressure relieve valves, are some of the more common valves used on board ships. Furthermore, most valves can be remotely operated via actuators and signals.

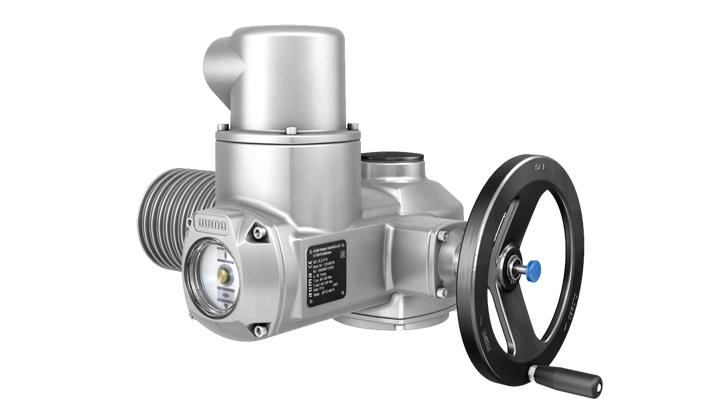

Actuators

AUMA - valve and machine actuators

AUMA has a generally modular product concept. From a wide range of modules, you can tailor actuators for any application. Clear interfaces between the individual components make it possible to utilize the many variants - always with high demands on the quality of the products and the ease of use of the AUMA actuators.

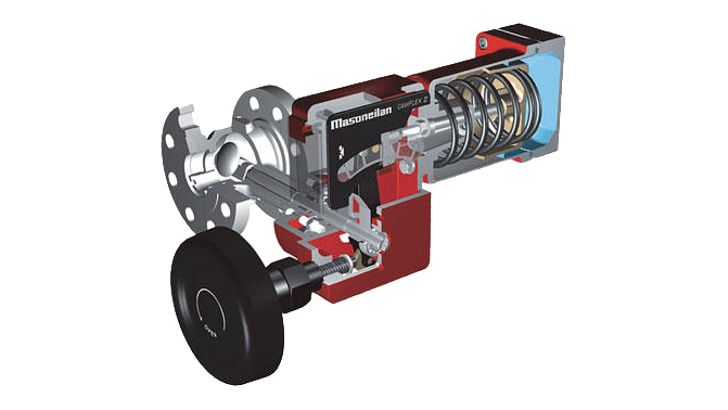

Control Valve

Masoneilan - Camflex ll 35002

The CamFlex II control valve from Masoneilan, consists of valve, actuator and positions, built together in a compact unit. It is an economical solution with flexibility, precise regulation and long life.

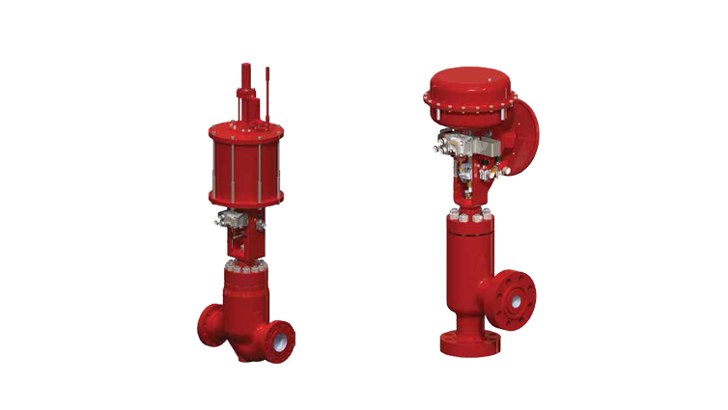

Control Valve

Masoneilan - 41005 Series

The Masoneilan 41005 Series is a robust control valve with balanced trim configurations. This valve is designed to provide you with efficient and stable operation under demanding process conditions, including applications with high pressure drops and large temperature variations.

Control Valve

Masoneilan - 28000 Varipak

VariPak 28000 is a compact control valve from Masoneilan designed for applications with a low flow. It has a wide range of options and capabilities to meet your desired requirements and needs. Furthermore, it is an economical solution, which provides flexibility, precise regulation and long life.

Control Valve

Masoneilan - 78400-18400 LincolnLog

The Masoneilan 78400/18400 Series LincolnLog valve offers longterm reliability in high-pressure, liquid-letdown, anti-cavitation control valve applications. Robust design with built-in stability to avoid vibrations / shaking, which ensures long life and reduces maintenance costs.

Safety Valve

Consolidated - Safety valve 1900

The 1900/P Series of safety valves from Consolidated is designed to easily adapt to a wide variety of application requirements and certified for gas, liquid and steam media. The flexible design allows you to easily replace parts and change the valve to other versions, such as converting from conventionak ti bellows design.

Accessories valves

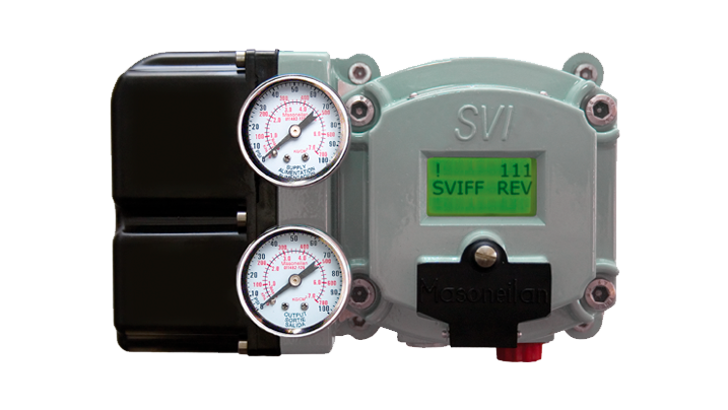

Masoneilan - Digital positioner SVI II AP

Digital positioner SVI II AP is a lightweight, simple and precise position from Masoneilan for controlling single or double acting pneumatic actuators. Available with HART protocol - 4 - 20mA and in safe class IP66.

Accessories valves

Masoneilan - Digital positioner SVi1000

SVi1000 Digital positioner from Masoneilan is a user friendly 4-20mA digital valve positioner with HART Protocol for single-acting pneumatic control valves with proven magnetic position measuring technology.

No results found

Valves

Basic – but Essential to Operations

Valves are used for many purposes and are available in just as many varieties. The basic function of a valve is to create a variable barrier between the two sides of the valve. Valves are most commonly used for three purposes; open/close, control or safety. Depending on what the valves’ intended use is, the characteristics can be very different in regards to shape, size and materials.

As valves are one of the most common items found on board most ships, they are crucial for the operation, functionality and safety of the vessel. It is therefore, critical to have them functioning and well maintained at all times. If the wrong valve malfunctions at the wrong time, it could lead to delays, additional cost and in the extreme case even disaster. Apart from the valves themselves, all the directly related components are just as vital, and whether it is an actuator, a postioner or a switch, the failure of one of these ‘sub components’ could have the same affect as a failing valve.

How Can We Help?

We offer some of the most commonly used quality manufacturers of valves and supporting components in our product portfolio, and we support all of them with spares and replacements. In addition, we can be of assistance with replacement valves of alternative make and model, as well as consulting on valve solutions for new/optimized systems. We have a dedicated valve team in-house, so regardless if you are looking for spares or a complete valve we can help you.

We cover most of the valve needs you might have. Should you have a need for a specific valve type or model that is not listed, you are more than welcome to contact us, and we will do our best to help you.