Torque & Thrust

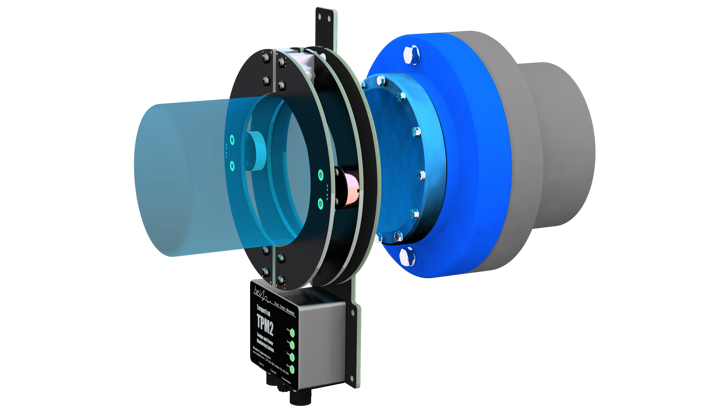

Binsfeld TorqueTrak TPM2 torque & power monitoring system

The Binsfeld TorqueTrak Torque and Power Monitoring System (TPM2 series) is a rugged precision instrument designed to measure torque and/or power on rotating shafts in real time using precise strain-gage sensors. The TPM2 is custom designed to fit on shafting as low as .75″ (19mm) and up to 48″ (1220 mm) in diameter. Machine disassembly is not required.

Torque & Thrust

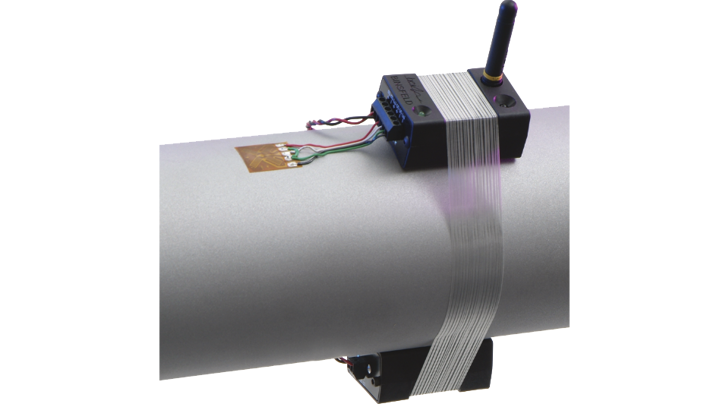

Binsfeld TorqueTrak Sensor Interface (TTSI)

The Binsfeld Engineering TorqueTrak Sensor Interface (TTSI) is an optional interface that connects fx. The TorqueTrak TPM2 with your other products / systems. The TTSI takes the Modbus signal from the torque meter and can transform it to additional analog or digital I/O. It’s made from off-the-shelf components and custom programming giving you a flexible and economical solution.

Torque & Thrust

Binsfeld Sea Trial Kit

Binsfeld Engineering’s Sea Trial Kit provides everything you need to measure shaft torque, speed, and power on your vessel during sea trials. The all-in-one system measures and records data for up to 2 shafts simultaneously, at a rate of up to 2400 Hz for torsional vibration testing. The components come in an easily transportable, robust, and compact case, allowing for easy set-up and transport of the system between jobs.

Torque & Thrust

Binsfeld TorqueTrak 10K Torque Sensor

The Binsfeld Engineering TorqueTrak 10K is a non-contact telemetry system ideal for real-time measurement of torque. The system is ideal for short-term data collection and diagnostic testing. It is designed to operate in harsh field conditions and is suitable for a wide range of applications, including marine propulsion systems, industrial machinery, and wind turbines.

Torque & Thrust

Binsfeld TorqueTrak SPM iON Torque Meter

The Binsfeld TorqueTrak SPM-iON is a cutting-edge strain gage solution that accurately measures torque, RPM, and power on rotating shafts without requiring shaft disassembly or alteration. With only two main components and no need for a base mount, installation is simple and lead times are quick thanks to the innovative chain link design.

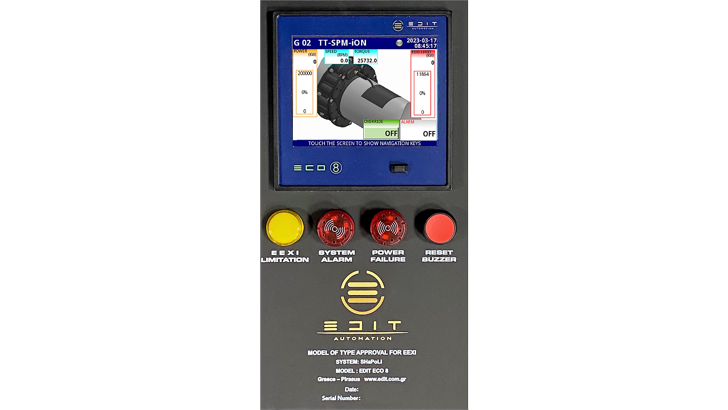

Shaft Power Limiter

EDIT ECO 8 ShaPoLi

The ShaPoLi ECO 8 uses an existing torque meter to limit the shaft power of your ship, thereby reducing the CO2 emissions in accordance with the IMO EEXI regulation. ECO 8 will help you monitor and record the shaft power and set the power limitations using any output signal. The solution has several type approval and OMM book certifications making it an obvious choice for your vessel.

Fuel & performance

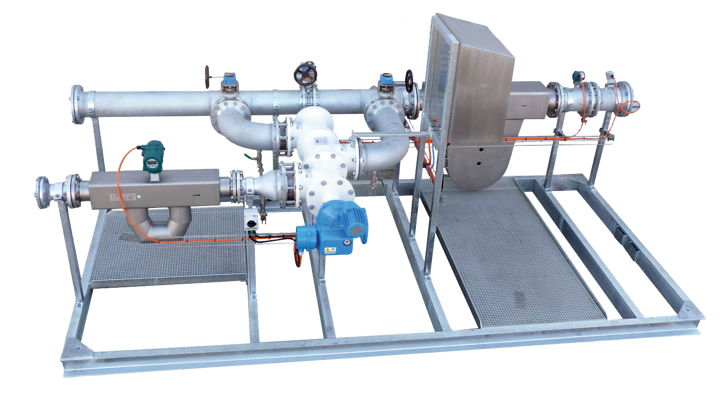

Insatech Bunker Management System

Insatech Marine’s Bunker Management System is developed, designed and constructed to act as a safeguard against manipulation of bunkered marine fuel oil as well as counteracting it. By using equipment and methods that deliver high accuracy inline and real-time measurement during bunker operations, any attempt by the bunker service to gain an economic advantage is detected. This ensures you have the upper hand in any possible disputes.

Fuel & Performance

Insatech Bunker Blending System

The Insatech Marine Bunker Blending solution ensures accurate blending and delivery of bunker fuel that meets ISO 8217 standards. Using Coriolis-based flow meters, the system measures mass and density directly, allowing precise control over fuel quality and quantity. The result: optimized use of gas oil and automatic documentation for full compliance and transparency.

Fuel & Performance

Insatech Fuel Consumption System

When you start measuring your fuel consumption with accurate flow meters you can gain great insights into the ships everyday consumption. It gives you the means to adjust how you sail and find the most optimal way that saves you money. It also shows you the change in consumption when you implement improvements like hull cleaning and gives you a basis to make data driven decisions.