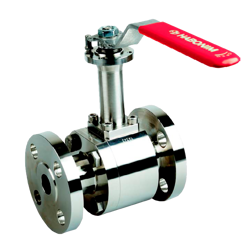

Metal seated ball valves from Habomim excels in the harshest industrial environments, where valve failures can damage plant efficiency, reduce profitability and endanger safety. Habonim’s meticulously engineered metal seated valve can withstand the harshest applications and process conditions, including extreme high temperature, high pressure and abrasive medium.

For sales or commercial inquiries please contact us at marine@insatech.com.