Start by “picking the low hanging fruits”

Operational efficiency in shipping is a condition for staying in business. Increasing crew awareness and knowledge of accurate fuel consumption is key to getting the most out of improvement projects and new procedures. And measurement accuracy is the cornerstone of securing the added profit when optimising the operation.

Maritime operation requires a high degree of attention towards operational efficiency and awareness on board vessels, both as a way to reduce costs but also due to legal and environmental requirements. Knowing your operation and basic consumption is a prerequisite for being able to determine fluctuations, and identify if/why an increased consumption has occurred. It is also important to know basic consumption when optimizing via performance improving investments in systems or equipment.

Since 50% – 70% of OPEX (Operating Expenses) is constituted by the cost of fuel, always knowing actual fuel consumption is worth your while. Add to the fuel cost the continuously increasing requirement regarding environmental issues; documenting your vessel’s number one contributor to emissions – the fuel – via an automated system will provide you with constant certainty of your emission levels. Measuring fuel consumption accurately and continuously is an obvious “low hanging fruit”.

Marine fuel flow meter accuracy matters

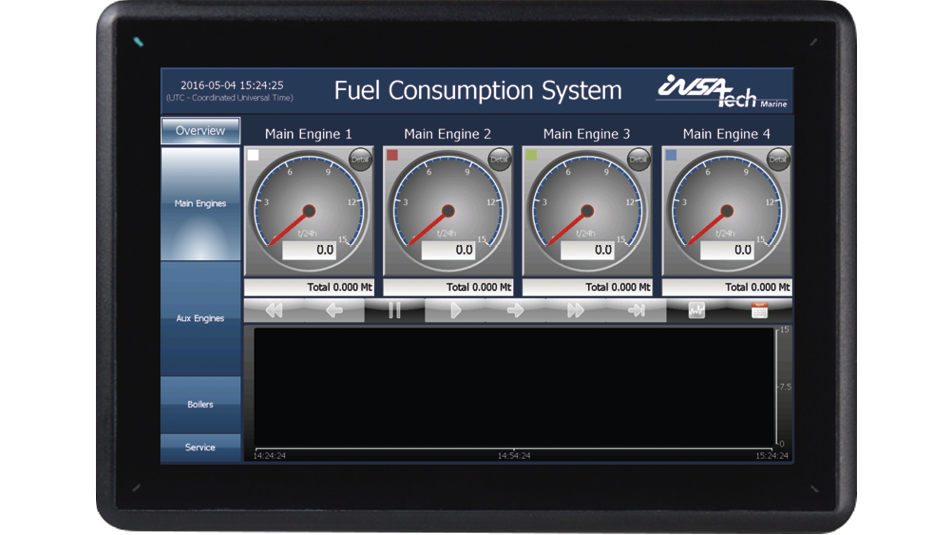

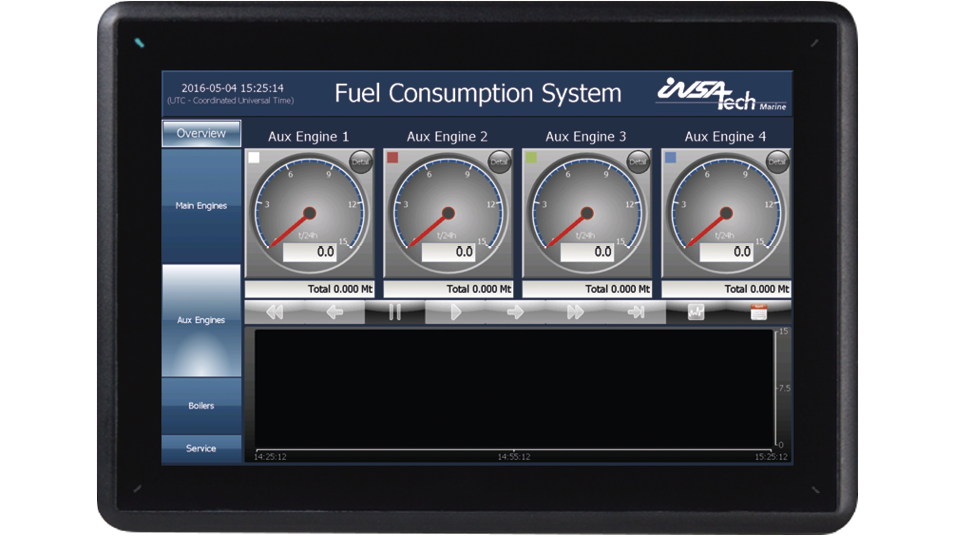

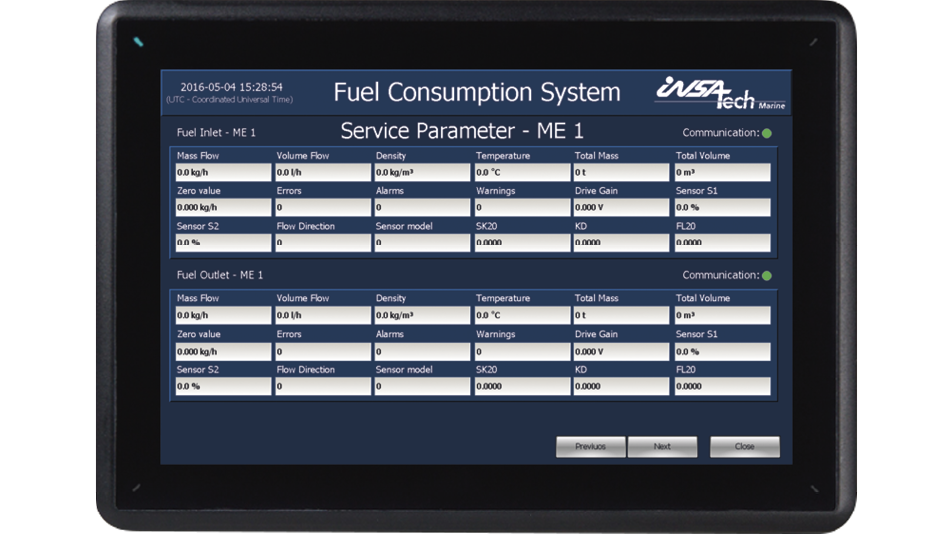

How much fuel is consumed on board a ship, is directly related to the performance. The better the performance, the lower the fuel consumption during operation. In this equation accuracy is not negligible. An offset of 1% in measurement on a vessel operating 200 days a year consuming an average of 100 tons a day equals an offset of 200 tons a year. Depending on the price of HFO or MGO used, this misread has the potential to range up to USD 100,000. The Coriolis Mass Flow Meters used in our Fuel Consumption System has an accuracy better than 0,2% of nominal flow directly measured in mass, whereas most volumetric flow meters are in the range 0,5% to 2,0% – and they rely on volumetric conversion which depends on the temperature to calculate a mass flow.

Know when you make money - and make more!

Without accurate measurements of the consumption of fuel on board, it is truly difficult to determine what effect any changes in installations, procedures or maintenance has had. Relying on either noon reports or measurement instrumentation of lower accuracy can make it very difficult to know the exact benefit of fuel saving projects – or at least delay the proof. Therefor the installation of a Fuel Consumption System is a way to increase your competitive advantage by freeing your crew’s hands from operation and maintenance of the instruments, which allows them to focus on their primary task - Optimizing the efficiency of the ship and thereby increasing profits.

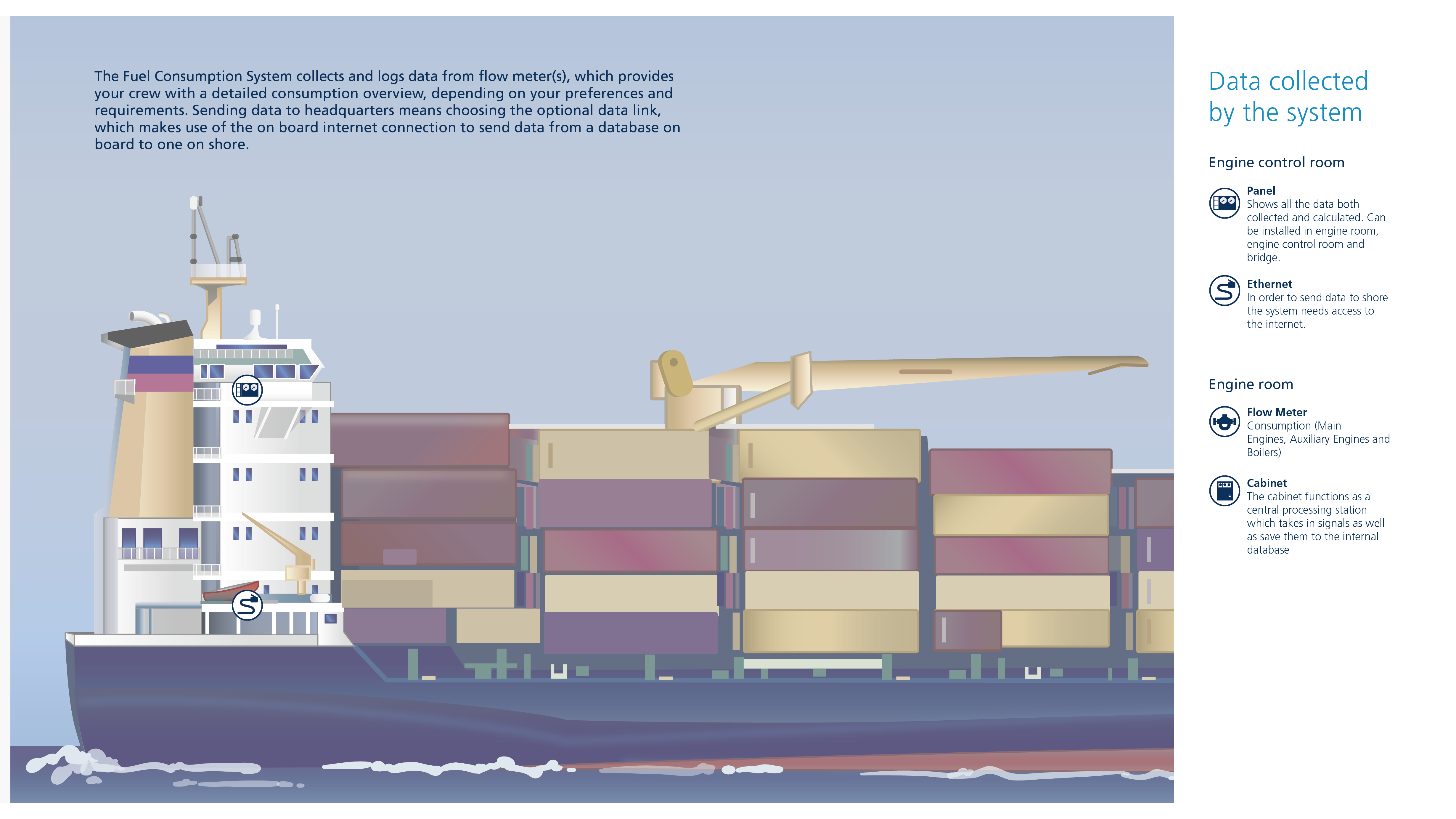

The Fuel Consumption System can also be upgraded to the Performance Monitoring System.