Cylinder Liner Diameter Measurement (CLDM-System)

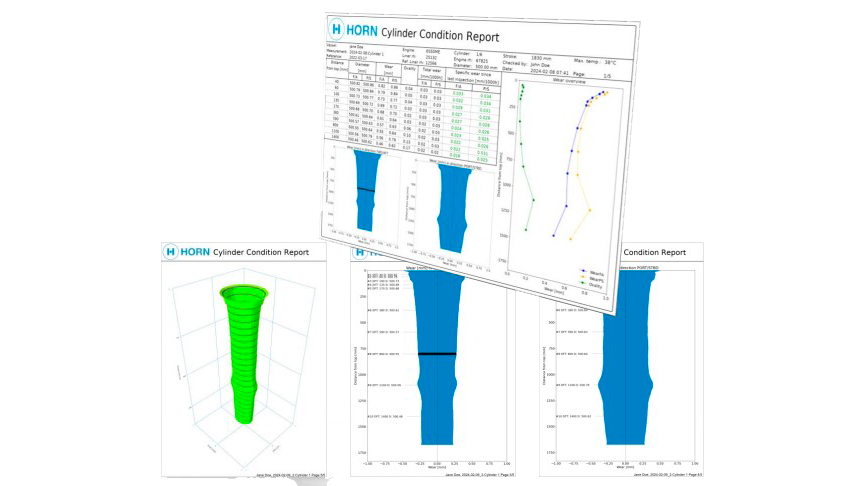

The CLDM system from Dr. E. Horn enables the crew to measure the liner wear of two-stroke engines without removing the cylinder head – directly through the scavenge ports. Equipped with high-precision eddy current sensors and bore-specific calibration, the crew can perform measurements quickly, reliably, and without external service providers. The recorded data is automatically analyzed by the supplied software, generating detailed reports in both 2D and 3D.

The CLDM have many advantages:

- Amortises in less than 18 months

- Operated by the crew without risk of mishandling

- Calibration checks possible at any time

We deliver directly and globally to end-users, agents, and resellers.

Contact us at quotes@insatech.com.