Diagnose Failures at Early Stage

The fundamental principle of the system revolves around measuring the thermos-voltage generated by a steel crankshaft as it glides along the metallic surface of its bearing shells.

The CPS signal serves as an early warning system, providing operators with crucial information regarding potential friction-related damages, particularly in the bearings. Through the display, operators are promptly informed about the condition, allowing for timely diagnosis of issues in the moving parts and preventing severe damage to the engine.

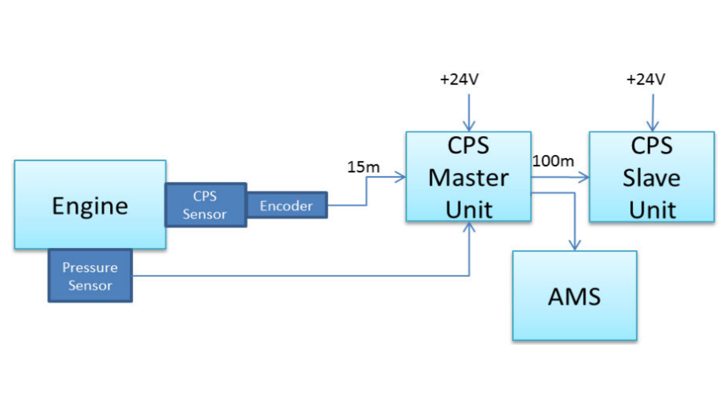

The system is also linked to the AMS system through pre-alarm and main-alarm relay outputs.

The CPS, along with its optional position encoder and pressure sensor, connects to the CPS Master unit, which calculates and monitors the measured values. Alarm level thresholds are established based on specific engine settings and parameters.

Directly connected to the AMS, the CPS Master Unit ensures a seamless integration.

Meanwhile, the CPS Slave Unit is responsible for displaying real-time data at the ECR, where measured values are showcased, and signal evaluation is carried out.

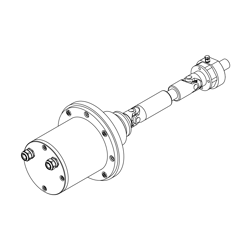

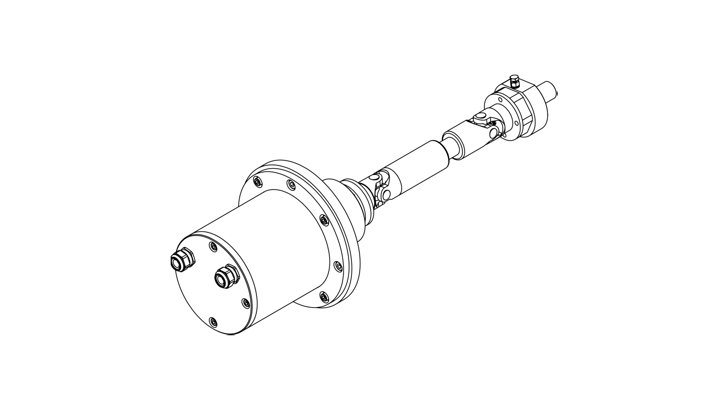

The CPS Sensor is installed on the housing, specifically on the free end of the crankshaft.