Working principle of the CLTS

Cylinder Liner Temperature Sensors continuously monitor the temperature levels of each liner within a marine engine assembly. The objective is to identify potential issues early on and safeguard the cylinder liner from irreversible harm.

Each liner will be outfitted with a pair of sensors, positioned in opposite directions. This arrangement aids in determining the most critical temperature level, regardless of installation tolerances and any air gaps present within the liner.

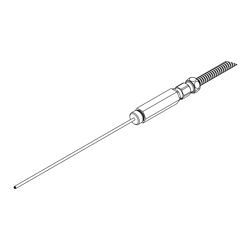

The sensors possess a highly rugged design, with the sensor tip capable of enduring temperatures up to 800°C, utilizing stainless steel materials. A spring mechanism inside the sensors allows for movement of the sensor tip, ensuring constant mechanical contact between the sensing element and cylinder liner. This ensures excellent thermal response and swift reaction times in case of overheating.

CLTS sensors come equipped with an evaluation board enclosed in housing GHG02731. Communication capabilities include a current loop of 4...20mA or I²C. This versatility makes the CLTS system suitable for monitoring temperatures in various applications, such as large gear units, plain bearings, and heavy-duty drives.