GLI Series

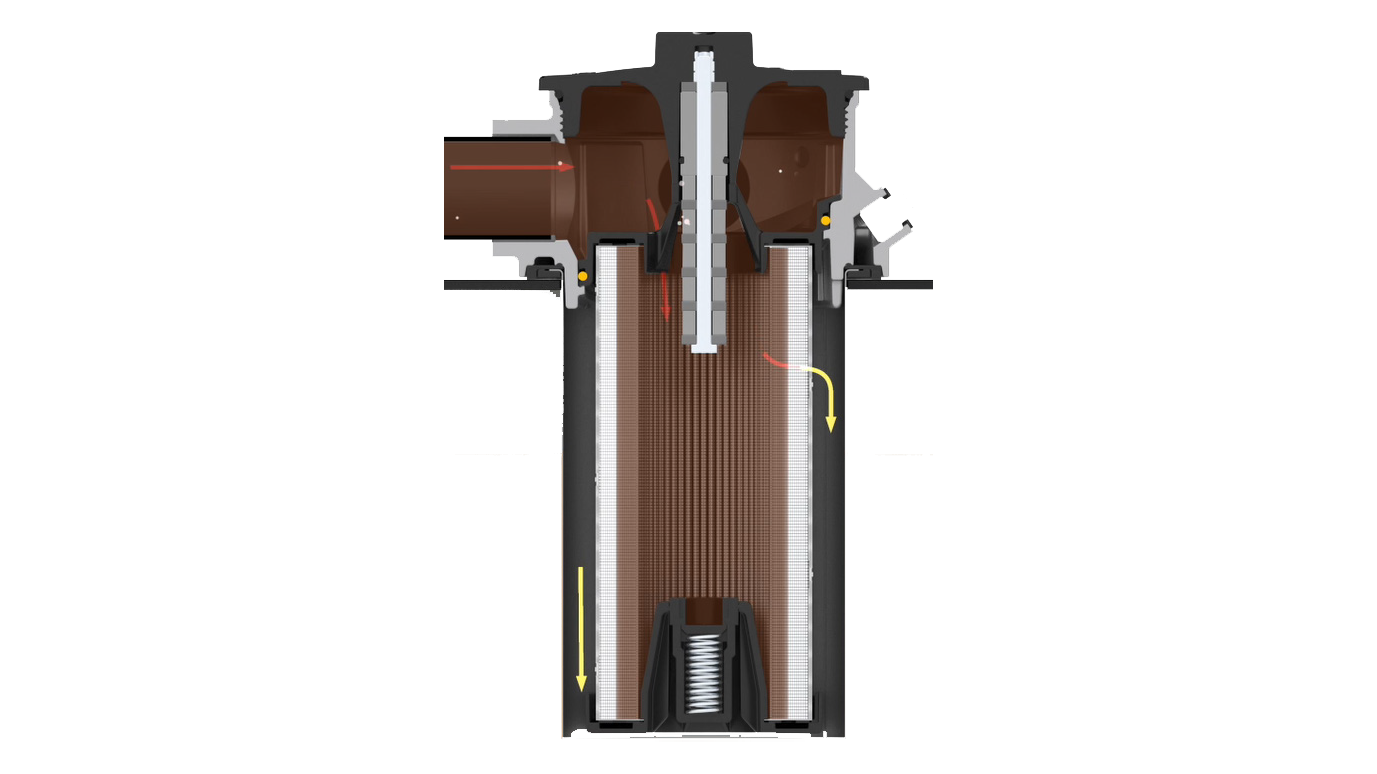

The GLI series from Parker are in-tank mounted return line filters, which are designed to provide high-quality filtration to hydraulic systems. Moreover, the filter reduces the cost of ownership by improving productivity and profitability.

Advantages for you:

- Cost-effective

- Compact

- Easy maintenance and fitting.

- No leak back of contaminated oil.

We deliver directly and globally to end-users, agents, and resellers.

Contact us at quotes@insatech.com.