Mechanical Flowmeter (OM Series)

FLOMEC Mechanical flowmeters offer the ability to handle a wide range of fluid viscosities because of the increased flow range. This gives you exceptional levels of repeatability.

Furthermore, these flowmeters are accurate, inexpensive in procurement, installation and maintenance.

More advantages:

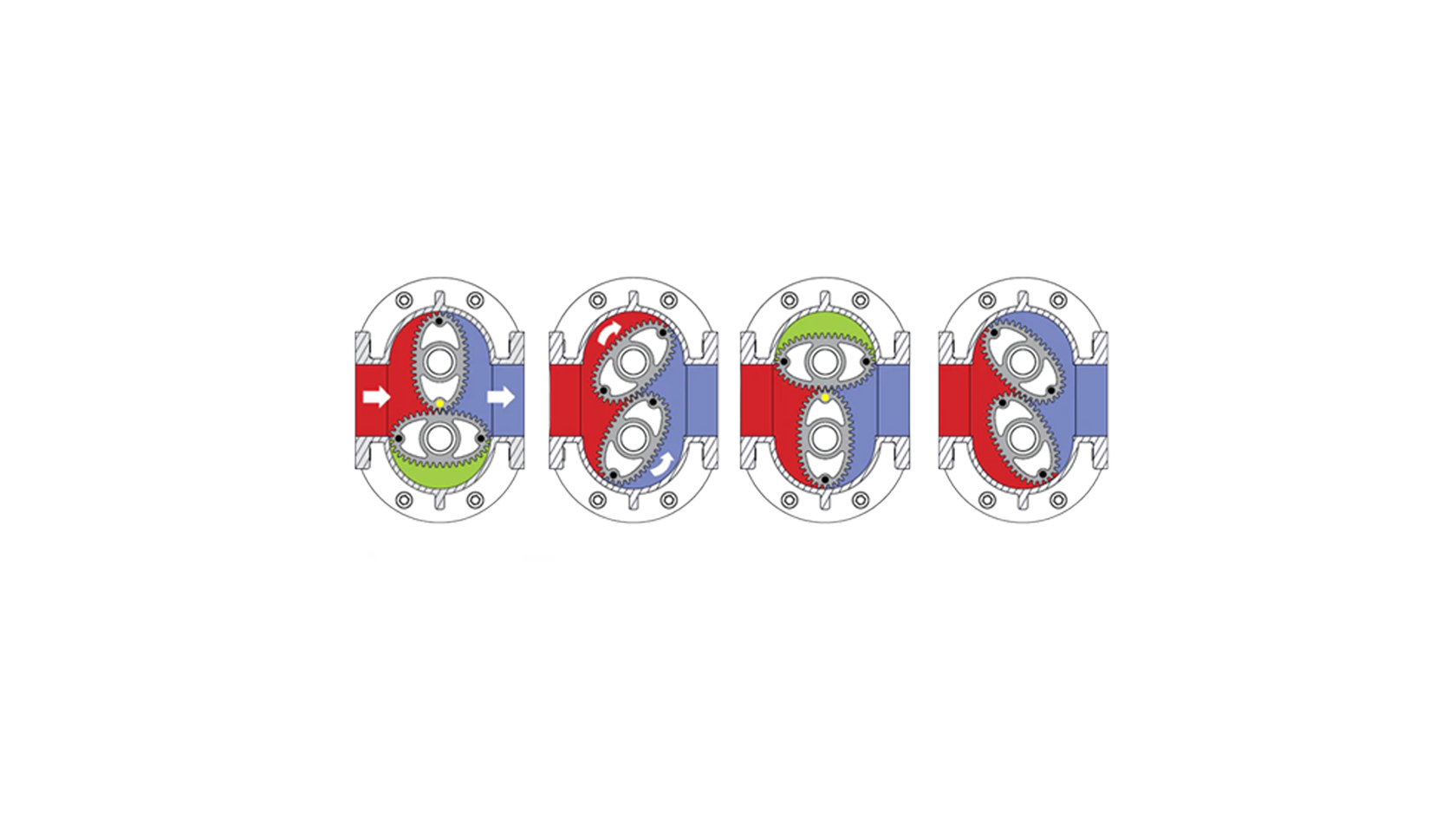

- High accuracy oval gear technology with low-pressure drop can be used in gravity-fed applications

- Measures liquids both of high and low viscosity

- No requirements for flow conditioning

- Only two moving parts.

We deliver directly and globally to end-users, agents, and resellers.

Contact us at quotes@insatech.com.