Operation

The Performance Monitoring System is fully automated and requires little attention after initial set up. The operator panel displaying the measured data can be customized to show your desired data.

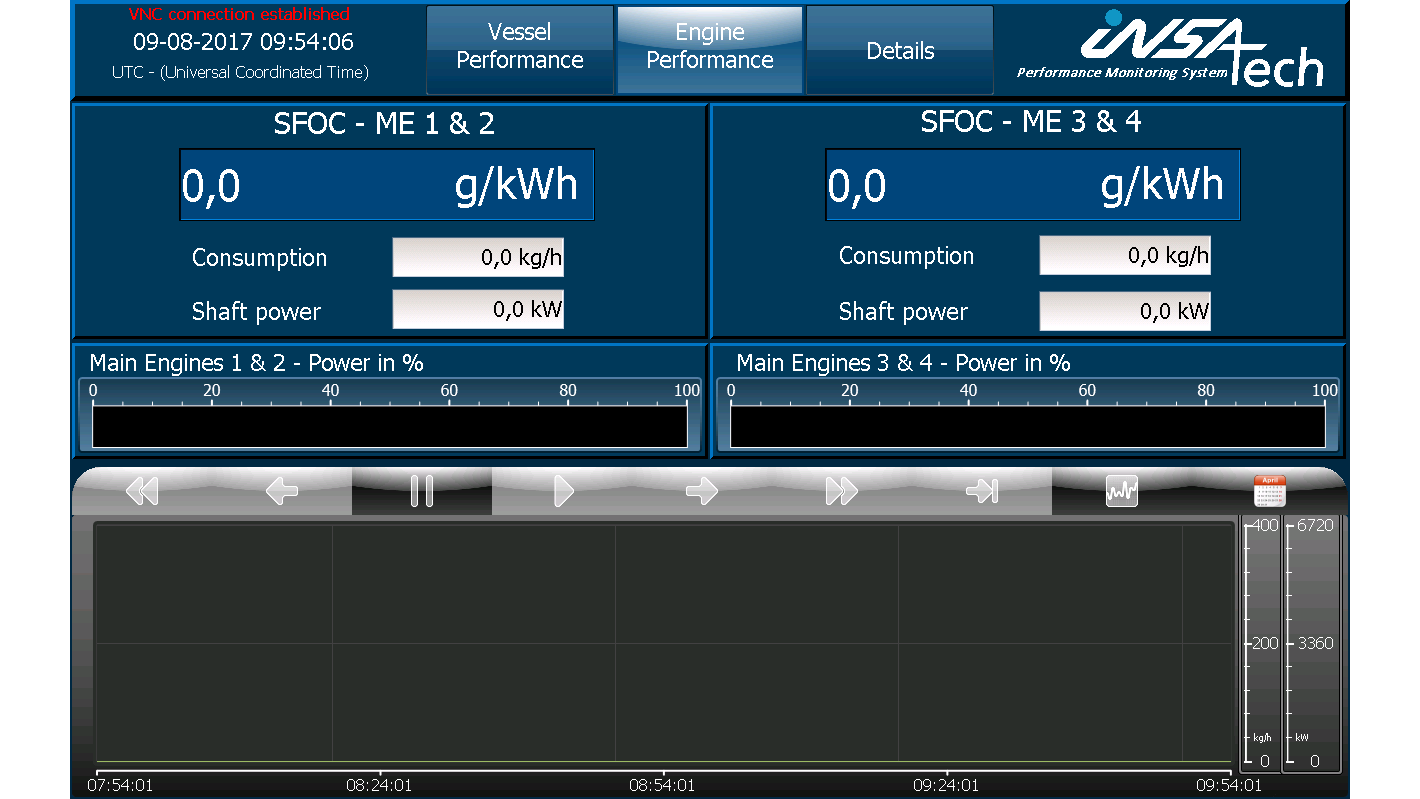

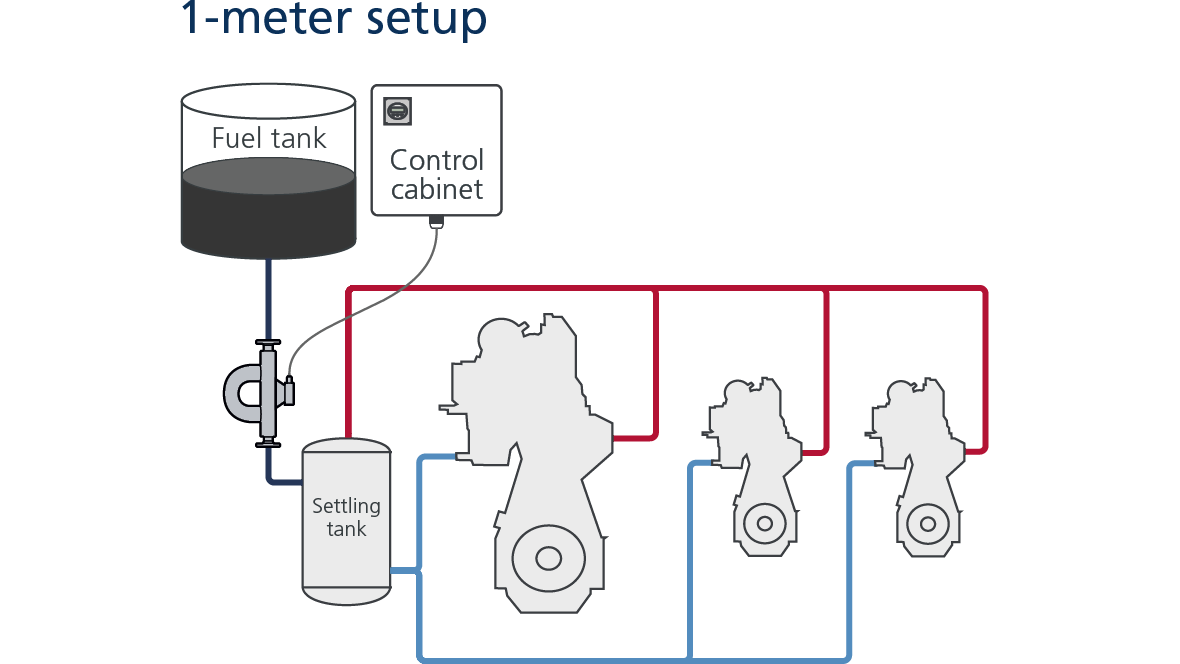

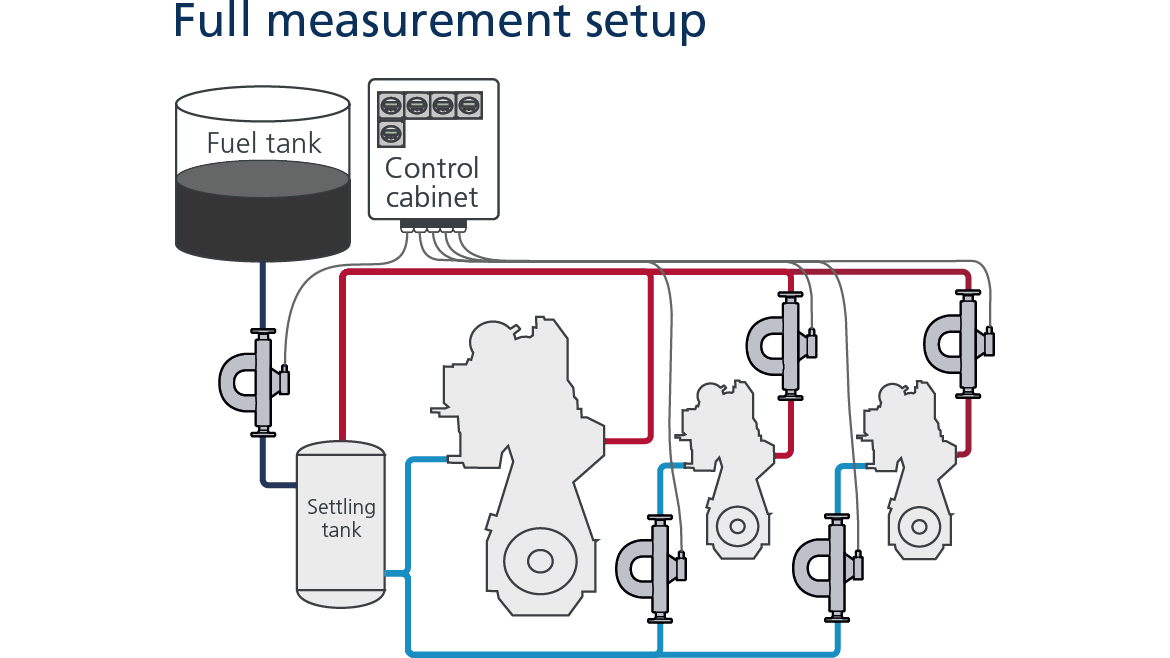

Spending less time operating equipment or reading manuals, means more time for improving the current operational status of the vessel. Therefore the Performance Monitoring System draws all the signals from instruments to a central processing station, the control cabinet. Here the data is used to calculate the vessel’s real-time performance. This is presented as KPI’s such as Specific Fuel Oil Consumption (SFOC) and kg of fuel per nautical mile (kg/Nm).

There are several advantages to real-time data and KPI’s as opposed to noon reports and manual readings. The KPI’s give the crew an insight into the ship’s performance that can help them sail the vessel more efficiently. This will in turn make your fleet more competitive, helping you win orders and save money. The automation of data collection will ensure that you get better data quality as well as quantity. Instead of data once a day you will get data once a minute.

This data can help you gain insight into how the vessel is being sailed right now, as well as being used to educate the crew on how to sail more efficiently. The automation will also free up crew time for other more important tasks.

Determine the influence of weather

With the motion sensor installed it is possible to determine the influences of weather on the ship. This is done by determining the state of the weather (wind and waves) for a limited period of time after the installation and manually inputting it into the system. Afterwards it will be possible to use the gathered data to calculate the ship’s performance under different weather conditions.

Decision making tool on board

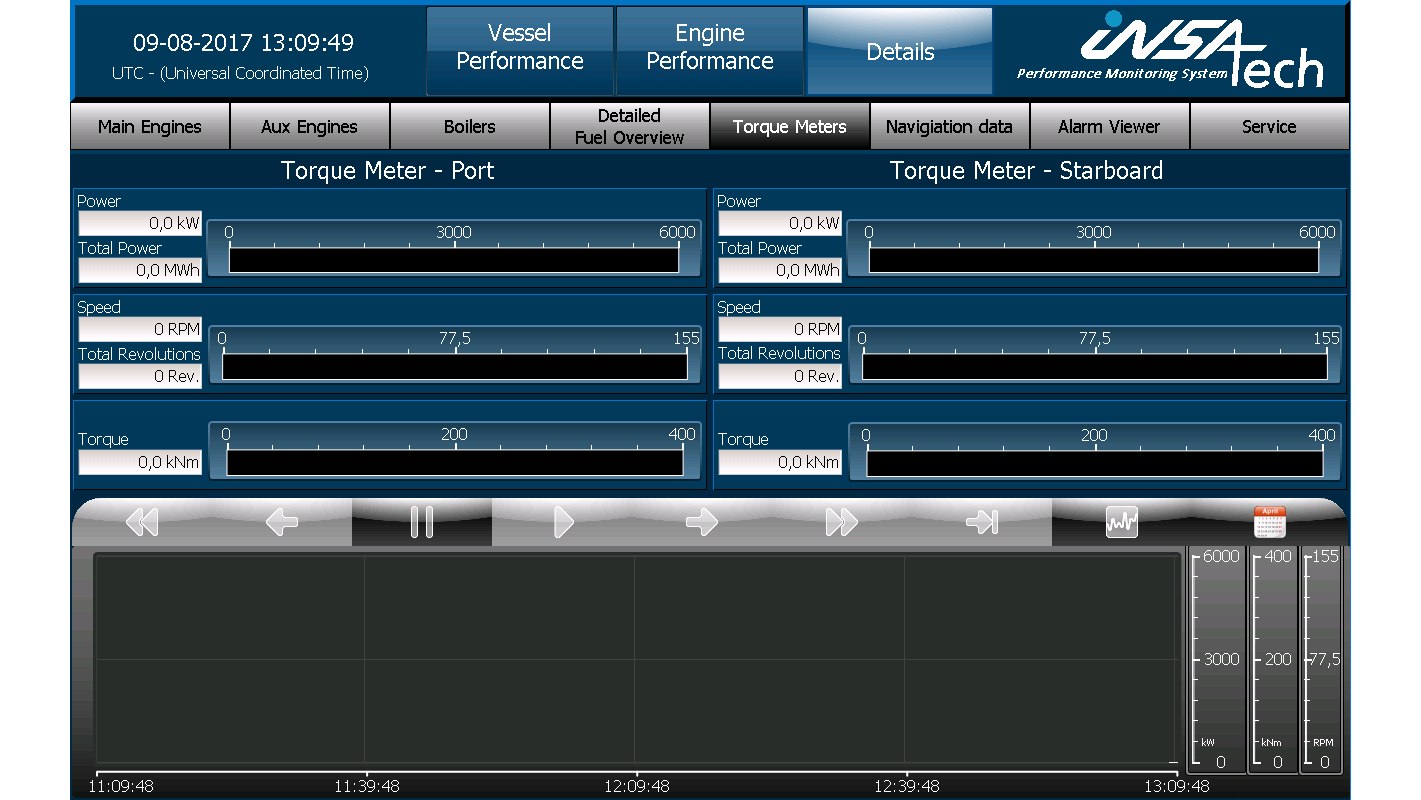

When the crew has the information available at all times, it allows them to view the immediate consequences of any actions taken and how it affects the vessel’s overall performance.

Using the KPI’s as main indicators of the vessel’s performance means that any change in conditions or operation affecting performance, will result in KPI changes.

As all readings are available centrally, running conditions of monitored vessel components can be checked right away. Troubleshooting as well as corrective and optimising actions can be identified a lot easier compared to manual visual inspections, and potentially lead to savings in fuel and crew resources.