TorqueTrak TPM2 torque & power monitoring system

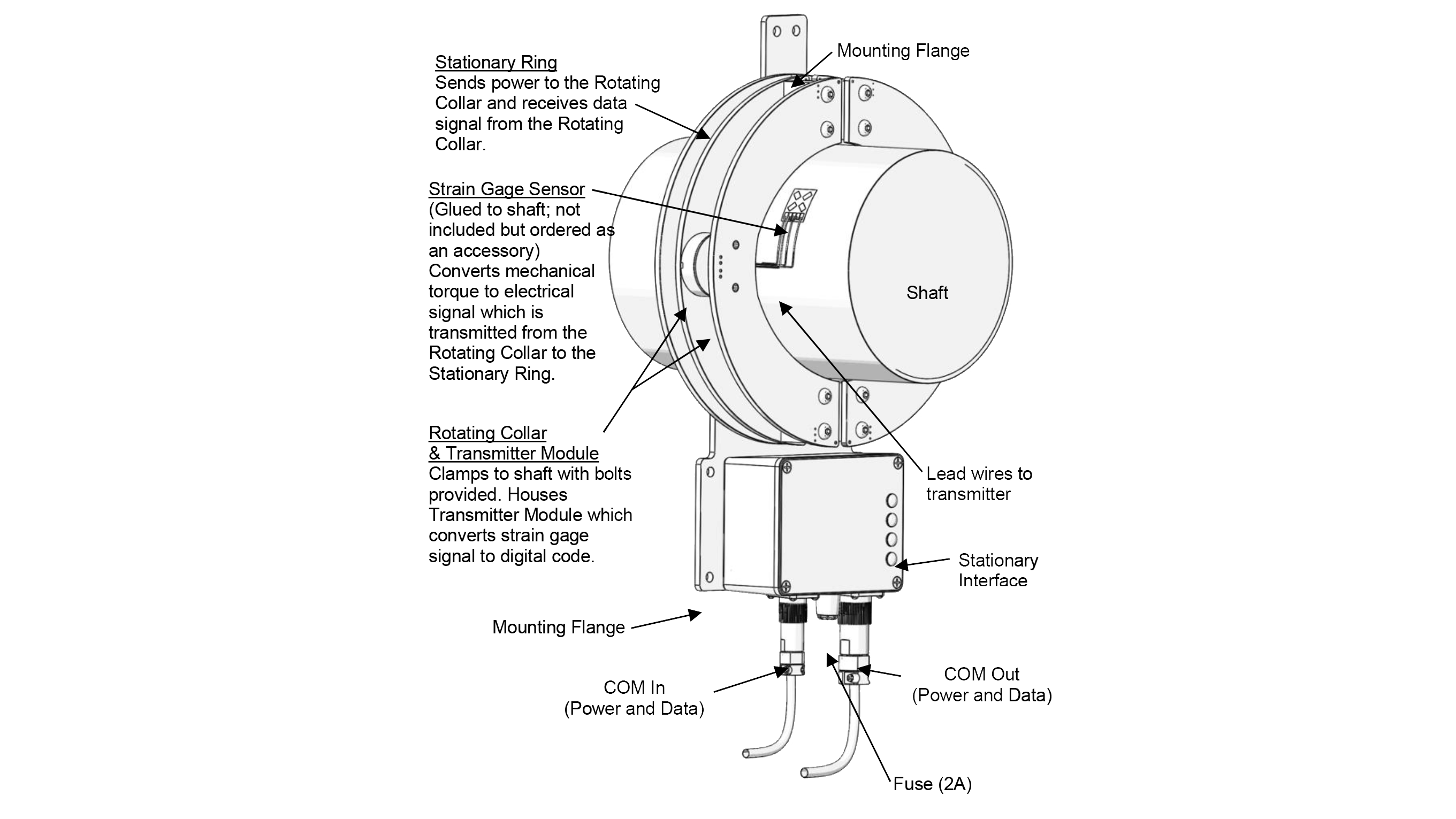

The TorqueTrak Torque and Power Monitoring System (TPM2 series) from Binsfeld Engineering is a robust, high-precision device meticulously crafted for real-time measurement of torque and/or power on rotating shafts. It employs precise strain-gage sensors for accurate data acquisition. The TPM2 is tailored to suit shaft sizes ranging from as small as 0.75 inches (19mm) to as large as 48 inches (1220mm) in diameter.

Key benefits for you:

- On-Time Calibration

- Real-time measurement

- Machine disassembly is not required

- Custom designed.

For sales or commercial inquiries please contact us at marine@insatech.com.