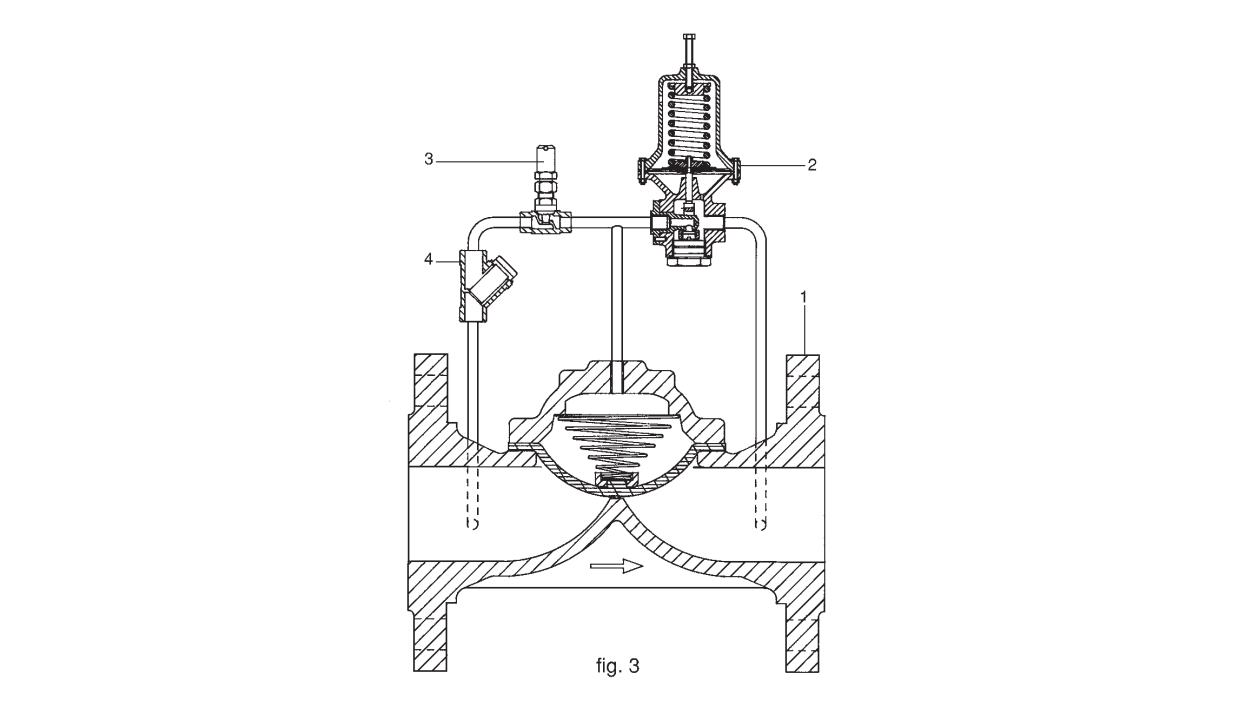

How the Maxomatic Valves Operates

The operation of the regulating device relies on three key components:

- The Diaphragm

- The Conical Spring

- The Pilot System.

The diaphragm functions as both a shutter and, along with the spring, as an actuator. Its design allows it to move smoothly between fully closed and fully open positions without strain. The position of the diaphragm is determined by a balance of forces.

In the closing direction, these forces include the combined actions of the spring and the servofluid (the medium itself), with pressure levels adjusted by the pilot system.

In the opening direction, the medium's pressure acts on the lower surface of the diaphragm.

The conical spring provides a force that increases proportionally with the diaphragm's lift, enabling it to respond appropriately when the servofluid pressure changes, ensuring stable operation without chattering.

The pilot system senses the controlled parameter and adjusts the servofluid flow to modulate pressure on the diaphragm, moving it to achieve the valve lift necessary to maintain the desired control.

Once the valve reaches the position needed to meet the required capacity, the pilot resets, allowing the system to maintain a steady flow, thereby completing the control process.