Condition monitoring instruments can, at a very early stage, help identify issues, that might lead to catastrophic failure. Since the monitored machinery does not require the crew’s attention, they can instead focus on more important tasks. In addition to freeing up the crew’s time, applying condition monitoring can also provide valuable information on operation and periodical maintenance optimization.

Magnetic Field Sensor

Dr. E. Horn Magnetic Field Sensor FGL01612

The FGL01612 from Dr. E. Horn is a sensor used for measuring magnetic fields. The sensor is used in combination with two other devices: the pulse amplifier (EV299013) and the magnet (MG003272).

Water in Oil Sensor

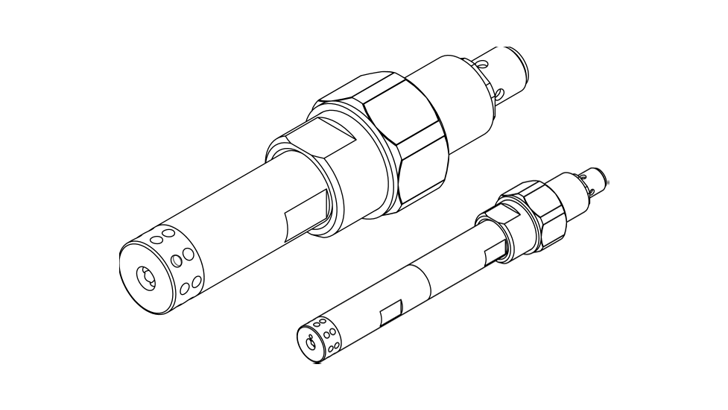

Dr. E. Horn Water in Oil Sensor (WiO System) New Generation FRG00035

The Water in Oil system from HORN consists of a sensor FRG00035, a main processing unit MPU010, or the connection box GHG02088-5.

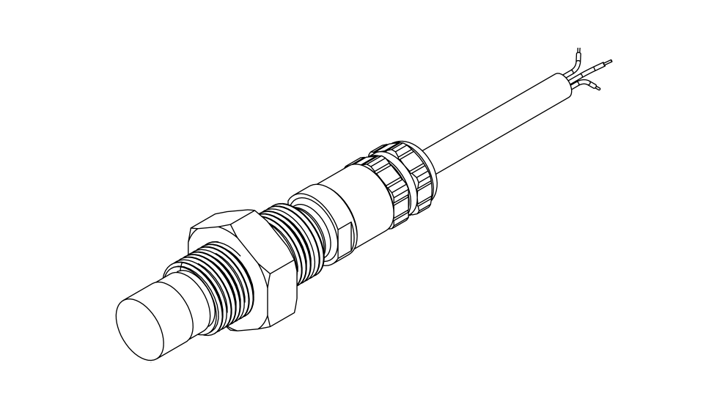

Distance Sensor

Dr. E. Horn Distance Sensor IW00016

The distance sensor IW00016 from Dr. E. Horn is composed of a metallic housing that contains the sensor components and, in some cases, the electronic components. This design ensures mechanical durability and prevents interference from external circuits.

Angle sensor

Dr. E. Horn Angle Sensor EDG50 Series

The angle sensor series EDG 50 from Dr. E. Horn has been meticulously crafted following the guidelines outlined in CiA 406: Device Profile for encoders, incorporating NMT slave functionality. The Node-ID can be conveniently chosen via hardwire or jumper settings, offering a selection of 7 distinct Node-IDs.

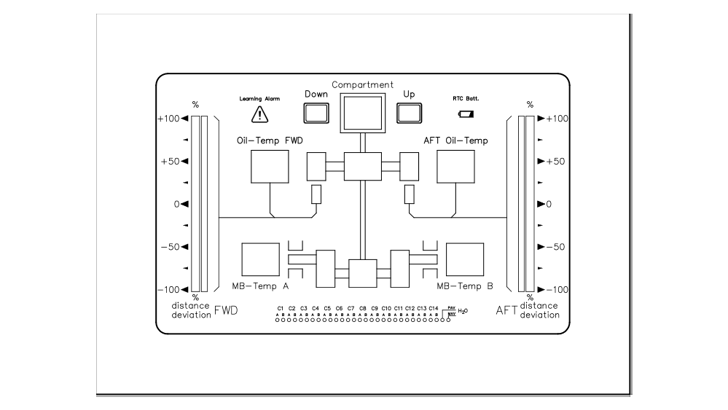

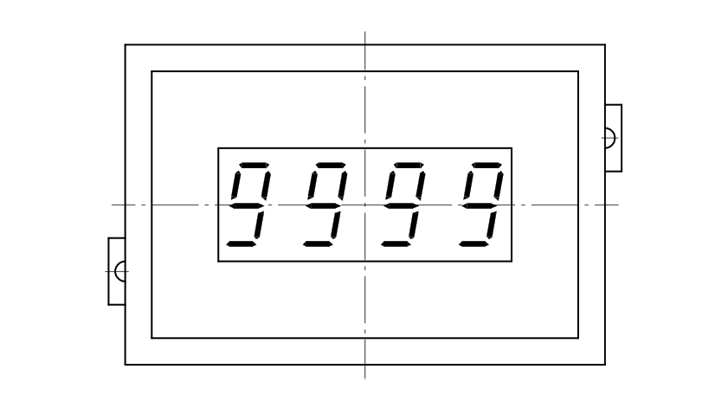

Digital Display

Dr. E. Horn Digital Indicator MDA 26

The MDA digital indicators from Dr. E. Horn are versatile and programmable instruments designed for various measurement applications. These digital touch panel can be customized to your needs and is available in two models: the Digital Indicator Programmable for U/I or Pt100 Input and the Digital Speed-Indicator with one Frequency Input.

Digital Display

Dr. E. Horn Digital Rate Indicator DA72-173

The DA72-173 from Dr. E. Horn is a digital rate indicator with a time base. It is a powerful tool for displaying a wide range of physical parameters such as speed, velocity, and flow rate. It operates by accurately determining the frequency represented as an electric voltage. The indicator is available also for hazardous areas.

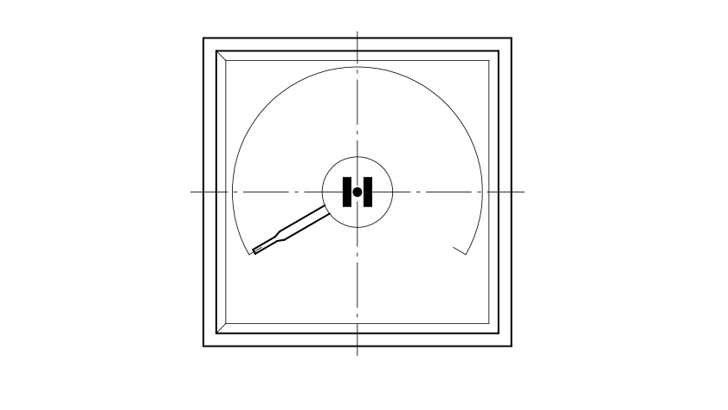

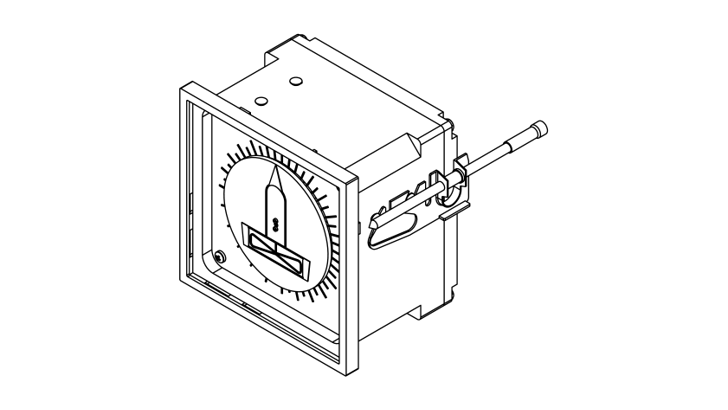

Analog Display

Dr. E. Horn Tacho Indicator EAF xxx

Dr. E. Horn tacho indicators of type EAF ... 5 offer a comprehensive solution for measuring and displaying pulse-frequency signals obtained from contactless sensors. These indicators incorporate a built-in measuring converter that directly converts the pulse-frequency signal into a driving direct current for the meter. The flexibility of these indicators allows for the allocation of any frequency range to any indication range within the specified technical limits.

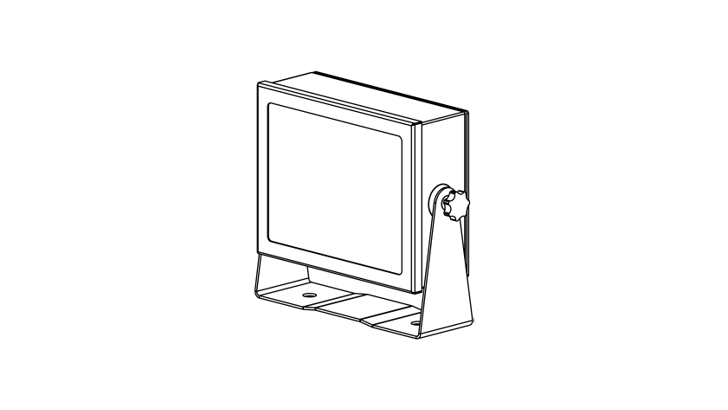

Analog Display

Dr. E. Horn EAD xxx Analog Display Unit

The EAD series from Dr. E. Horn is an analog display unit specifically designed for usage on ships. This series of analog displays have multiple advantages over gauges employing moving coils.

Analog Display

Dr. E. Horn Tacho-Indicator EA xxx

The tacho-indicator EA xxx from Dr. E. Horn is the ultimate solution for remote tachometry. The analog display is designed to meet the demands of even the most challenging operating conditions, our robust moving coil instruments deliver unparalleled accuracy while requiring minimal maintenance.

No results found

Condition Monitoring

No One Wants a Vessel Taken Unexpectedly Out of Operation. Enter Maintenance!

Breakdowns and malfunctions are never welcomed and can lead to heavy repair costs and loss in earnings, which is why maintenance of equipment is critical. Maintenance schemes and programs have become better over time as focus has shifted from reactionary maintenance towards a more preventive oriented approach.

By avoiding shutting down systems for repairs and planning maintenance work based on experience and calculations, a lot of time and money has been saved, as well as many stressful situations for the crew has been dodged. But, how do you actually know that the preventive maintenance carried out, is not done too excessively and too often, thus actually costing more than necessary? By imple-menting condition monitoring as a concept, you can enable crew and operators to gain an insight in the actual ‘health’ of main and auxiliary systems on board.

What Is ‘Condition Monitoring’?

The term ‘condition monitoring’ covers a very wide array of products that are designed to provide indications about a systems’ operational health. When using condition monitoring, the crew and operators can get actual insight about a particular system’s condition by directly analyzing the system or component.

The condition monitoring equipment will provide you with information about wear, tear and present failures. By carrying out systematic and periodical analysis of your equipment you can prevent unexpected failures and plan your maintenance more wisely, saving time for your crew and money on equipment repairs.

How Does it Work?

As condition monitoring is a definition that includes many different products, it can work in just as many ways. But in general the condition monitoring equipments look for things that are out of the ordinary for example particles in lube oil, contaminants in fuel oil or specific vibrations of engines, shafts and generators.

By continuously monitoring the day to day operation the crew cannot only determine if maintenance is required but also identify the root cause.

The upper section contains a collection of condition monitoring equipment, that can assist in optimizing maintenance efforts, identify and prevent critical failures before they happen and minimize down-time by scheduling optimally. If you are looking for something specific and it is not found here, please contact us and we will see what we can do to help you.