High-Precision Coriolis Flow Meters: Ensuring Accuracy in Marine & Industrial Applications

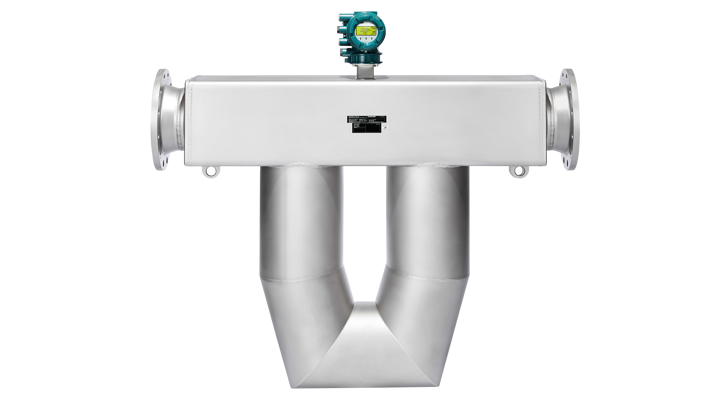

In the last decade, Coriolis flow meter technology has evolved from a general-purpose tool into a critical asset for high-stakes industrial applications. By measuring mass directly rather than volume, these meters eliminate the variables that often lead to costly discrepancies - particularly in the marine industry during bunkering operations.