Fuel remains the most significant expenditure in commercial shipping, typically accounting for 50–70% of a vessel's total operating costs. In an era of fluctuating prices and tightening environmental regulations, the ability to accurately measure and manage fuel, from the bunker barge to the engine, is a fundamental requirement for profitability and compliance.

Precision Bunker Management Systems (BMS)

Insatech Marine specializes in high-precision Bunker Management Systems designed to eliminate the "Coriolis vs. Sounding" discrepancies often encountered during fuel transfers. Our solutions utilize Coriolis Mass Flow Meters to provide direct mass measurement, ensuring that what is paid for is exactly what is delivered.

-

Custody Transfer Accuracy: High-fidelity measurement that eliminates the errors associated with manual tank soundings and volume-to-mass conversions.

-

Aeration (Cappuccino Effect) Detection: Advanced signal processing to identify and compensate for air entrainment in fuel lines, protecting your financial interests during bunkering.

-

Real-time Monitoring: Instant visibility into flow rates, density, and temperature for both receiving vessels and bunker barges.

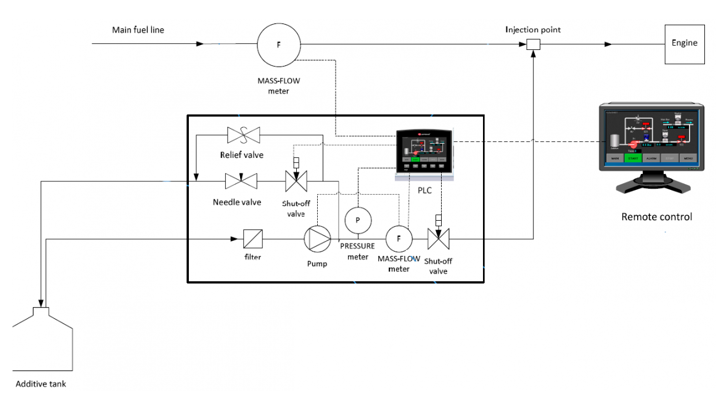

Optimized Fuel Conditioning and Additive Dosing

Managing fuel does not end at the intake manifold. Our automated systems ensure that fuel is conditioned and treated with surgical precision before it reaches the combustion chamber.

-

Automated Additive Dosing: Maintain precise chemical ratios to improve combustion efficiency and reduce emissions, controlled via high-speed closed-loop logic.

-

Fuel Consumption Monitoring: Synchronized data logging that provides a clear baseline for Specific Fuel Oil Consumption (SFOC), enabling technical managers to identify performance degradation in real-time.

Compliance and Decarbonization

Modern fuel systems are the frontline of regulatory adherence. By providing unalterable, timestamped data, Insatech systems simplify compliance with CII (Carbon Intensity Indicator), EU ETS, and MRV requirements. Our "single-source" approach ensures that your fuel telemetry is audit-ready, integrated with existing shipboard systems, and supported by global service experts.