Knowing exactly how much media is present in a tank or how much product is in a cargo hold is essential for running a ship. The measurement is usually performed by a level instrument using methods such as radar, ultrasonic, electrical capacity, floaters (relays) or pressure. A level measurement can be used in many applications e.g. automating the loading and transfer of cargo, ballast water and fuel to their respective tanks as well as ensure the stability of the vessel via level based trim monitoring.

Level switch - Liquids

VEGASWING 51

Level switch for liquids - standard version - 40mm forks. Typical applications will be overflow, overflow and dry run protection.

Level switch - Liquids

VEGASWING 61

Versatile level switch - used for almost all liquid applications. Typical applications will be overfill or dry run protection.

Level switch - Liquids

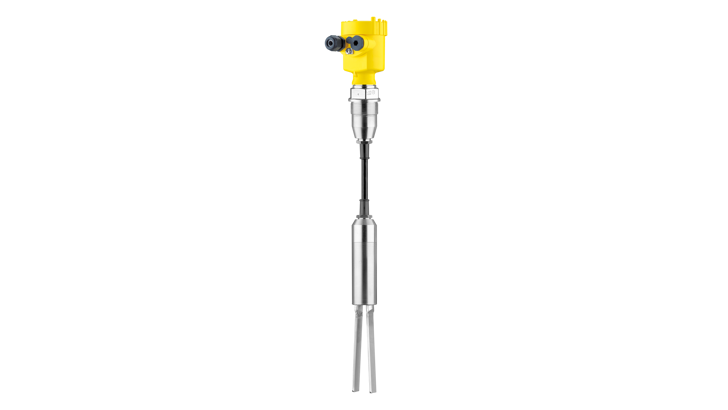

VEGASWING 63

Versatile level switch - variable insertion length - is used for almost all liquid applications. It's also a reliable instrument in high viscous media.

Level switch - Liquids

VEGASWING 66

Level switch to extreme temperature. compact instrument or with pipe extension up to 6m. Various supply options in Ex areas.

Level switch - Bulk solids

VEGAVIB 61

Versatile level switch - used for applications with bulk solids. Intended for Border Indication in Dry Media. It could, for example be overfill or dry run protection. Can also detect solids in water from -50 ... 150 ° C.

Level switch - Bulk solids

VEGAVIB 62

Versatile level switch - used for applications with bulk solids - cable version. Intended for Border Indication in Dry Media. It could, for example be overfill or dry run protection. Can also detect solids in water from -20 ... 80 ° C.

Level switch - Bulk solids

VEGAVIB 63

Versatile level switch - used for applications with bulk solids - rod version. Intended for Border Indication in Dry Media. It could, for example. be overfill or dry run protection. Can also detect solids in water from -50 ... 150 ° C.

Level switch - Bulk solids

VEGAWAVE 61

Versatile level switch - used for almost all solid-state applications. It could, for example. be overfill or dry run protection. Can also detect solids in water from -50 ... 150 ° C.

No results found

Level

The Basics of Level Measurement

Level measurement is basicly measuring the quantity of a product within a vessel/tank. This could be either a soild or liquid substance like oil, chemicals or coal. The level measurement device is usually placed on the top of the vessel or the bottom/side depending on the measuring princible.

When doing a continuous level measurement a level transmitter detects the level of a medium in a tank and converts it into an electrical signal. The level signal can be displayed locally or incorporated into an on board management system.

A point level detection is a level transmitter which detects when a certain predefined level is reached. A switching command starts or stops filling equipment or similar from the sensor signal.

We offer level sensors across all the different measuring principels which includes:

- Radar

- Guided Wave Radar

- Ultrasonic

- Capacitive

- Hydrostatic

- Radiation-based

- Vibration

Guidance to Choosing the Correct Level Sensor

We have been supplying level sensors of almost all types for decades, and we know which type of instrument would be most appropriate for your application, based on your requirements to accuracy, conditions where it should be used and what your end-purpose with the sensor is. We will gladly assist you in choosing the correct instrument with the desired characteristics and features, and we aim to provide a satisfactory solution to your needs the first time. Regardless if your focus on accuracy, special ambient conditions, ease of installation or price. As we have all supporting functions in-house, we can even help you with installation, maintenance, repair or up-stream signals integration.