Insatech delivers high-performance industrial valves for marine applications and demanding process environments across energy, oil & gas sectors. We supply robust Ghibson butterfly and check valves for shut-off, regulation, and backflow prevention, as well as Carraro safety and control valves for critical pressure management – all backed by expert technical support.

Actuators

Ghibson - Electric Actuators - Bernard

Electric actuator from Ghibson, adapted to their butterfly valves and ball valves. Media temperature from -20 ° C to + 70 °C and protection class IP 67 (IP 68 on request).

Actuators

Ghibson - Electric Actuators - NA

Quarter-turn electric actuator "NA series" is designed to operate ball valves and butterfly valves. The actuator is strong and robust.

Actuators

Ghibson - Hydraulic actuators

Ghibson’s own manufactured hydraulic actuators (ARES series) are designed to fulfill the specific requirement in industrial applications: compact design and high performance are the main characteristicsof this product range.

Check Valve

Ghibson - Wafer Check Valve GA015

The Wafer Check Valve GA015 from Ghibson is available in DN 15 to DN 100 - 1/2” to 4”, Pmax 52 bar. Furthermore, you can get it with a house, disc, seat plate, and spring in stainless steel and other materials on request.

Check Valve

Ghibson - Wafer check valve GB 015

Ghibson - Wafer check valve GB 015 is available in DN 15 to DN 100 - 1/2” to 4”, Pmax 52 bar. Moreover, it is small in size, low in weight and can be installed in all positions. Available with house, disc, spring, and top ring in stainless steel.

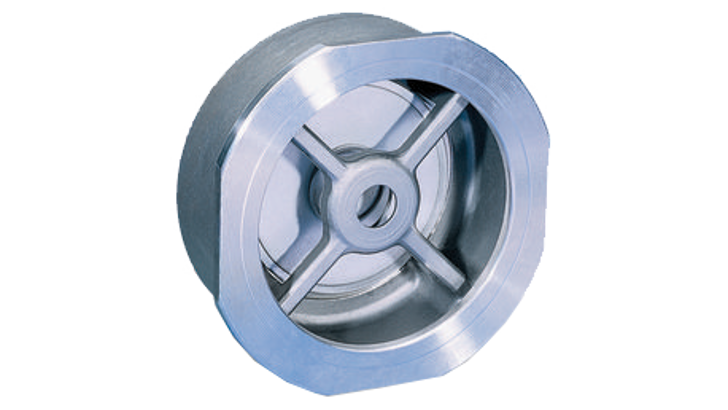

Check Valve

Ghibson - Wafer check valve GB 023

Ghibson - Wafer check valve GB 023 is available in DN 15 to DN 100 - 1/2” to 4 ”, Pmax 6 bar. Moreover, it has an opening pressure from 20 to 500 mbar. Available with house, disc, and seat in PTFE.

Check Valve

Ghibson - Wafer check valve GN 011

Ghibson - Wafer check valve GN 011 is available in DN 15 to DN 100 - 1/2 ”to 4”, Pmax 52 bar. Moreover, it is small in size, low in weight, and can be installed in all positions. Usable also as vacuum breacker, overpressure and bottom valve. Disc, spring, and seat in stainless steel and house in galvanized steel.

Check Valve

Ghibson - Wafer check valve GN 015

Ghibson - Wafer check valve GN 015 is available in DN 15 to DN 100 - 1/2 ”to 4”, Pmax 52 bar. Moreover, it is small in size, low in weight, and can be installed in all positions. Usable also as vacuum breacker, overpressure and bottom valve. House, disc, spring, and seat in stainless steel.

Check Valve

Ghibson - Wafer check valve GN 091

Ghibson - Wafer check valve GN 091 is available in DN 15 to DN 100 - 1/2 ”to 4”, Pmax 52 bar. Moreover, it is small in size, low in weight, and can be installed in all positions. Usable also as vacuum breacker, overpressure and bottom valve. House, disc, spring, and seat in hastelloy.

Previously known as GN115.

No results found

Valves

Insatech offers a comprehensive selection of industrial valves designed to handle liquids, gases, steam, and aggressive media across marine and industrial environments. Our valve solutions include shut-off valves, control valves, butterfly valves, and check valves - all available with manual, pneumatic, or electric actuation.

For advanced automation, we provide control valves with Masoneilan positioner, enabling seamless integration with SCADA or PLC systems. Every valve is engineered for durability, accuracy, and long-term reliability, making them ideal for both process industries and marine-grade applications. As an experienced industrial and maritime valve spare parts supplier, we also ensure full support with fast delivery of components, from actuators to seals.

With trusted brands such as Ghibson, Carraro, Masoneilan, Consolidated and Habonim in our portfolio, you get proven quality backed by expert technical guidance.

Valve Types We Offer

- Ball Valves

Reliable isolation during maintenance or emergencies. Available in ball valves and gate valves, ideal for process lines and shipboard systems.

View all Ball valves here - Control Valves with Masoneilan Positioner

Precision-engineered valves for modulating flow, pressure, or temperature. When equipped with a Masoneilan positioner, they enable smart diagnostics, accurate adjustment, and integration with industrial automation.

View all Control valves here - Ghibson Butterfly Valves for Ships

Ghibson butterfly valves for ships are compact, fast-acting, and corrosion-resistant – making them ideal for ballast water systems, bilge handling, and cooling circuits in marine environments.

View all Butterfly valves here - Carraro Valves for Oil and Gas Plants

Carraro valves for oil and gas plants are built to withstand extreme pressure, aggressive media, and harsh temperatures. Their robust design ensures long-term performance in both upstream and downstream operations. - Check Valves

Prevent reverse flow and protect pumps and process lines. Suitable for vertical or horizontal installation and often used in energy, chemical, and water systems.

View all Check valves here - Safety Valves

Provide overpressure protection in critical applications. Automatically release pressure to maintain system integrity.

View all Safety valves here

Industries and Applications

We support a broad range of industries with tailored valve solutions:

-

Marine industry: Corrosion-resistant valves, especially Ghibson Butterfly valves for ships, designed for durability in seawater and fuel systems

-

Oil & gas: Full valve packages including Carraro valves for oil and gas plants and safety systems

-

Energy and utilities: Control and safety valves for steam, water, and heat distribution

-

Industrial automation: SCADA-ready solutions using control valves with Masoneilan positioner

Valve Spare Parts Supplier

As a full-service valve spare parts supplier, we deliver original components for all the brands we represent – including Ghibson, Carraro, and Masoneilan. From seals and actuators to positioners and control modules, we ensure reliable long-term performance with fast turnaround on replacements and service kits.

Our spare parts offering includes seals, actuators, positioners, diaphragms, and control modules – all selected for compatibility and durability. We also supply essential accessories such as air sets to support stable and efficient valve operation. A key example is the Masoneilan Air Regulator Type 78, which ensures clean, regulated air supply for pneumatic actuators and positioners in demanding environments.

Get in Touch with Our Experts

For commercial inquiries

Our team of Sales Specialists

Tel.: +45 5537 2095

Email: quotes@insatech.com

We Deliver Directly to End Customers, Resellers, and Agents – Globally

At Insatech, we are proud to offer our high-quality products to all customers worldwide. Whether you’re an end customer, a reseller, or an agent, you can purchase directly from us.

By choosing us, you gain direct access to all our products, eliminating the need for intermediaries. Our global distribution possibilities ensure fast and reliable delivery to your doorstep, wherever you are.

We strive to make it easy for you as an end consumer to find the products you are looking for while supporting agents and resellers looking to grow their business. Whether you’re buying for your use or resale, we’re here to meet your needs.

Discover how simple it is to work directly with a trusted global distributor – shop with confidence at Insatech today!