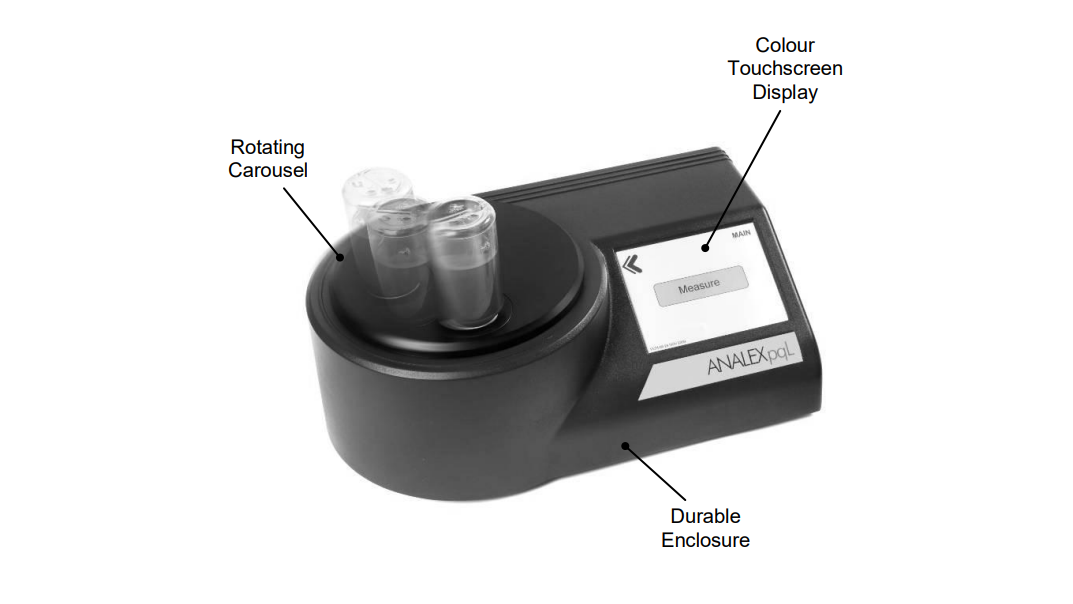

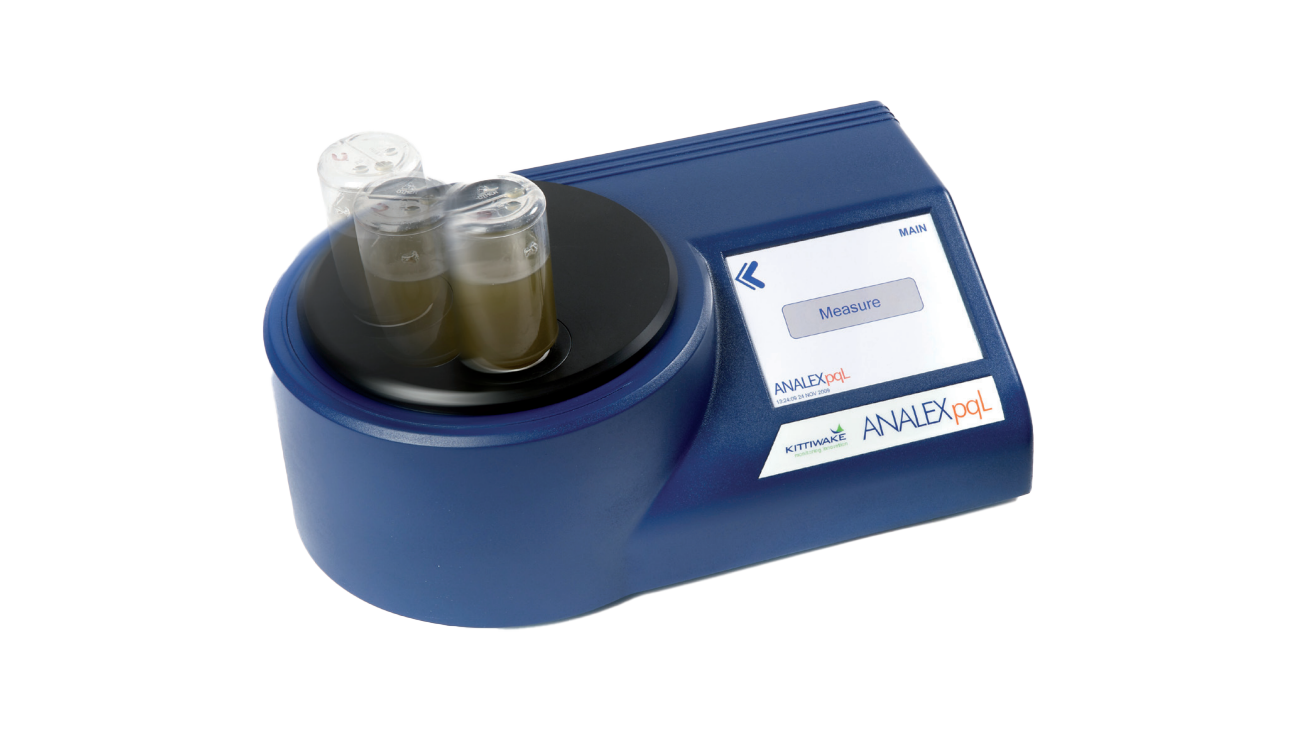

ANALEX pqL PQ Index Wear Debris

The ANALEX pqL from Parker Kittiwake is developed to replace the widely used pqM and pqA. Using all new hardware, software and the latest technology, the highly accurate device measuring ferrous wear debris, irrespective of particle size and distribution. The only available instrument, which is ASTM D8184 compliant.

This gives you the benefits of:

- More samples processed

- Quicker screenings

- Easy integration

- Simple to use.

We deliver directly and globally to end-users, agents, and resellers.

Contact us at quotes@insatech.com.