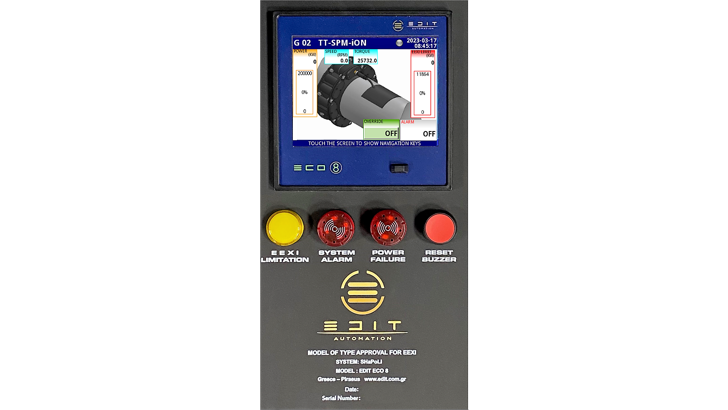

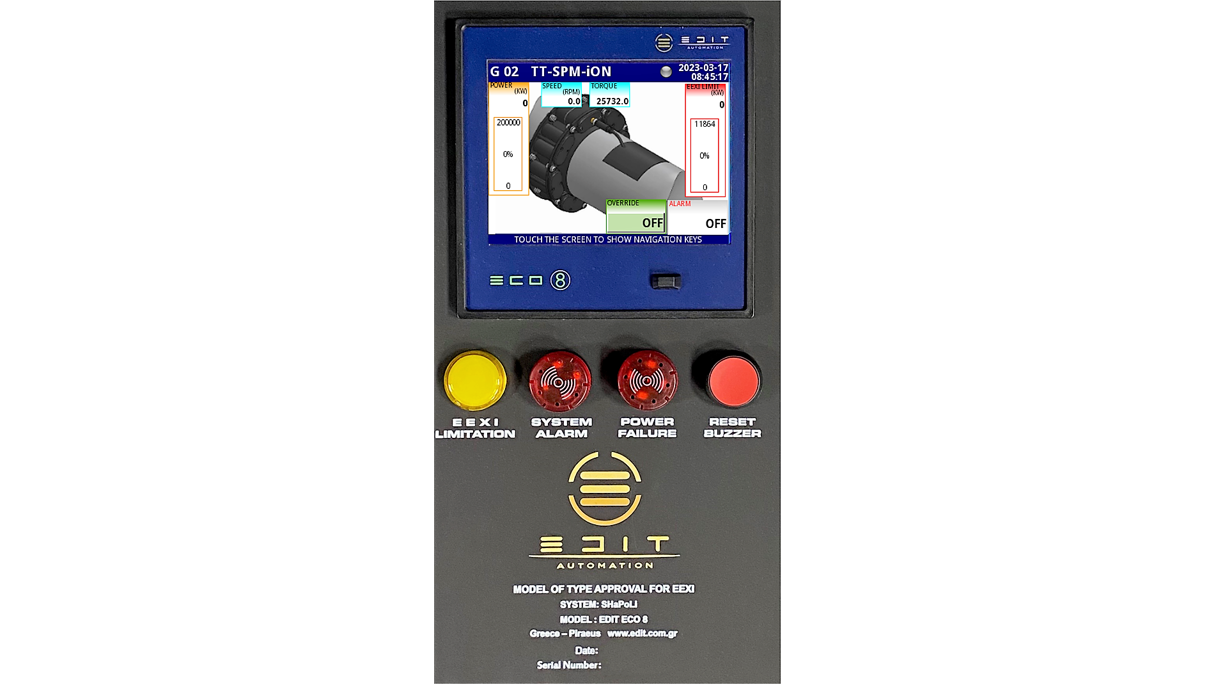

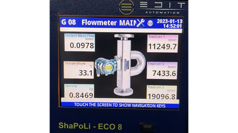

ShaPoLi ECO 8

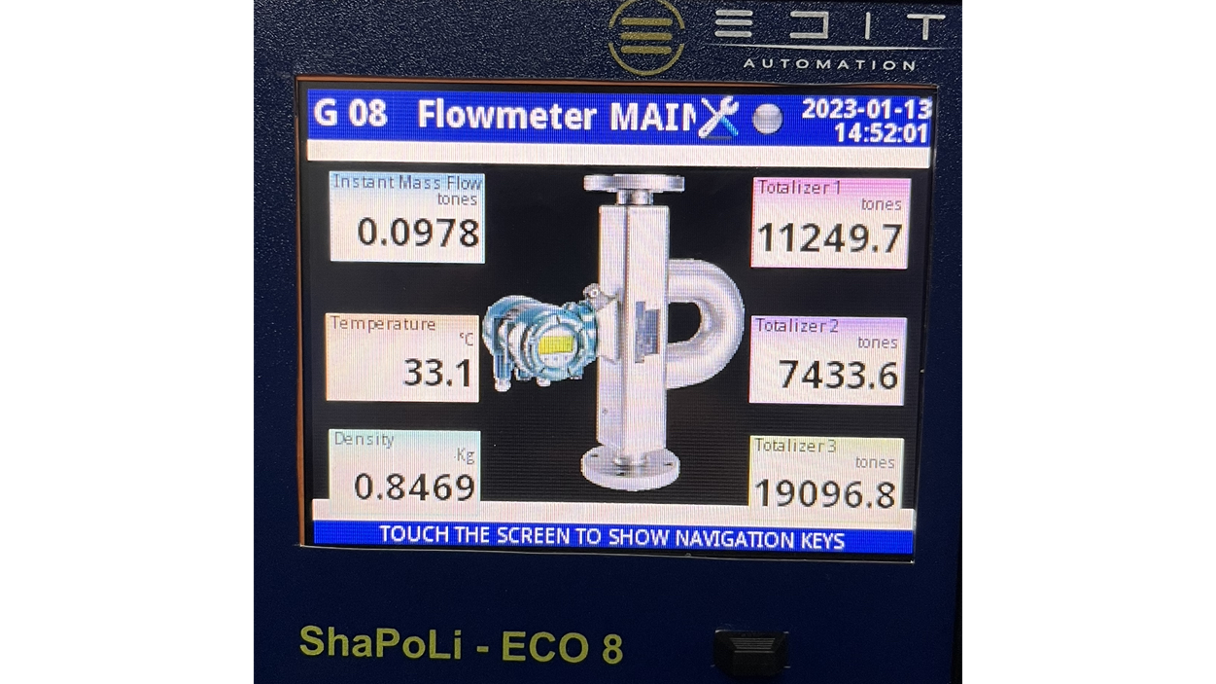

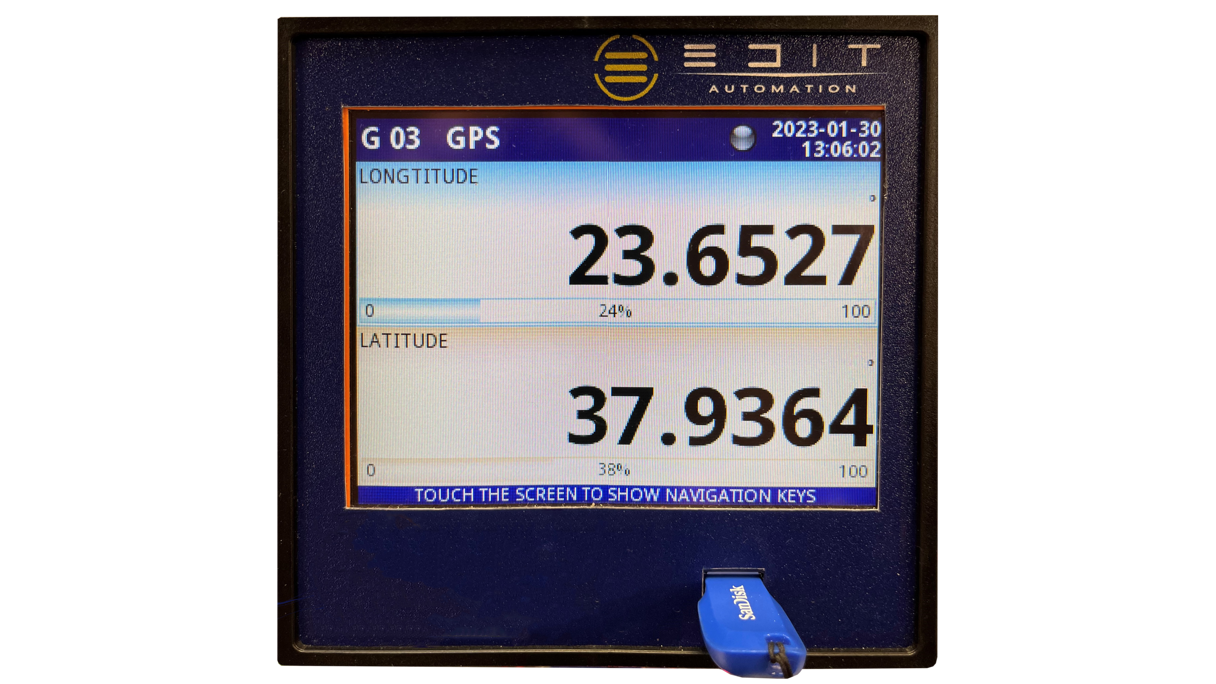

The ShaPoLi ECO 8 from EDIT Automation uses an existing torque meter to limit the shaft power of your ship, thereby reducing the CO2 emissions in accordance with the IMO EEXI regulation. ECO 8 will help you monitor and record the shaft power and set the power limitations using any output signal. The solution has several type approval and OMM book certifications making it an obvious choice for your vessel.

Your advantages:

- Cost-effective EEXI compliance.

- Quick and hassle-free installation.

- Compatibility with additional performance monitoring equipment.

- Rapid preparation and deployment.

- Seamless addition to existing shaft power meter systems.

- Certified compliance.

We deliver directly and globally to end-users, agents, and resellers.

Contact us at quotes@insatech.com.