Butterfly valves play a critical role in regulating and controlling the flow of liquids and gases in industrial processes. Our range of butterfly valves is designed to meet the diverse needs and challenges faced by modern industries.

Butterfly Valve

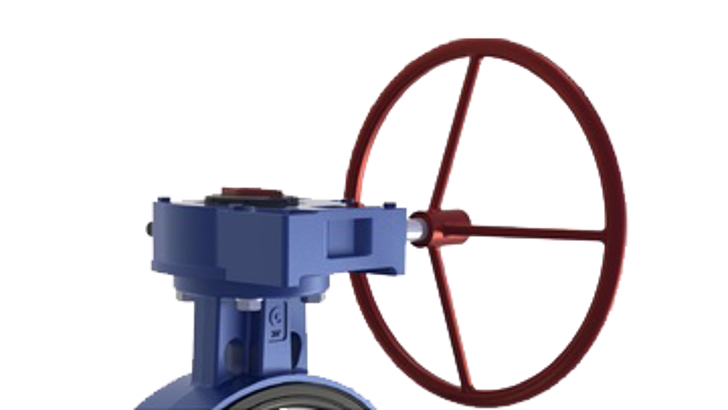

Ghibson - Butterfly Valve HD

The butterfly valves HD-series from Ghibson are high-performance valves, which are specifically designed for high-demanding applications where the valve performance is critical. This kind of valve is available in different materials and ratings.

Butterfly Valve

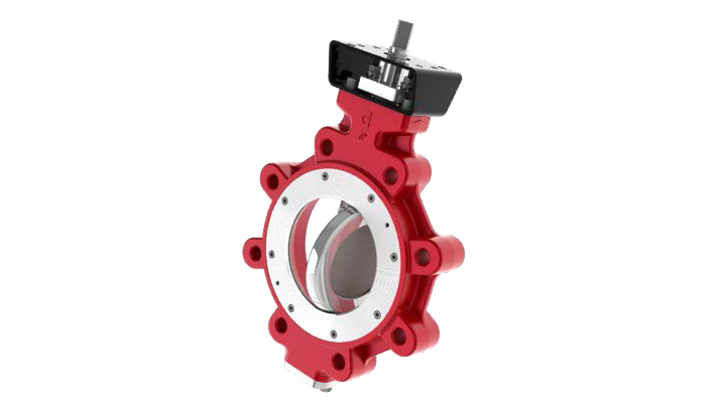

Ghibson - Butterfly valve TT

Ghibson PTFE seated butterfly valves TT series are available in a wide range of materials combinations, and are specifically designed for heavy duty applications and the chemical industry.

Butterfly Valve

Ghibson - Butterfly valve PD

Soft seated butterfly valves. The PD-series is designed for low pressure (max. 6/10 bar), produced in many different materials and avalieble with wafer (BVPD) and lug (BLPD) body.

Butterfly Valve

Ghibson - Butterfly valve KI

KI-series butterfly valves from Ghibson are soft-seated valves designed for marine applications. They are available in wafer body, lug body, and double flange configurations and can also be used in vacuum environments, Maximum pressure rating of 16 bar.

Butterfly Valve

Ghibson - Butterfly valve KA

KA-Series Soft seated butterfly valves are designed to meet with most industrial and maritime applications. Manufactured with sizes from DN 40- 800, pressures up to 20 bar and many different materials. To be used also with vacuum.

Butterfly Valve

Ghibson - Butterfly valve KX

The KX-series from Ghibson, are soft seated butterfly valves engineered to meet the demands of the marine industry. Available in both wafer body and lug body designs, with sizes from DN 50-250. A wide range of material options. The valves can be used with vacuum applications and feature a vulcanized body rubber seat.

Butterfly Valve

Ghibson - Handle for butterfly valves

Handles are normally only used up to and including DN 200, for larger sizes it is recommended to use gearboxes instead. The handles are available in either aluminum or stainless steel.

No results found

Butterfly Valves for Marine & Process Industry

Butterfly valves play a critical role in regulating and controlling the flow of liquids and gases in industrial processes. Our range of butterfly valves, including Ghibson butterfly valves, is designed to meet the diverse needs and challenges faced by modern industries.

Butterfly Valves for the Process Industry

Precise control of liquid and gas flow is essential in industrial systems, and our butterfly valves are tailored to provide robust and reliable performance across a wide range of process applications. Some models are even built to withstand extreme temperatures up to 1000 °C.

Applications

- Demanding industrial applications

- Chemical processing

- Harsh environments

- Marine butterfly valves for shipboard systems

- Temperature resistance up to 1000 °C

Material Selection

Choosing the right material is critical for every application. That’s why we offer butterfly valves with various combinations of body, disc, and liner materials. Available materials include Stainless steel, Hastelloy, Duplex, Super Duplex, EPDM, FKM, NBR, RTFE, and Inconel 625.

Seat Options

We supply butterfly valves with multiple seat types, including soft seat butterfly valves and PTFE-seated designs. Smaller valves often feature replaceable seats, while larger valves are available with vulcanized, non-replaceable seats.

Designs and Types

Our butterfly valve selection includes Wafer, Lug, and Double Flange types to fit different installation requirements. Flange types depend on the specific model; see individual product specifications for details.

Sizes and Pressure Classes

- Sizes up to DN1500

- Process pressures up to 25 bar

- Pressure ratings up to PN25

Accessories and Customization

Depending on the model, our valves can be customized with handles (recommended only up to DN200), gearboxes, actuators, stem extensions, and lockout/tagout features.

Get in Touch with Our Experts

For commercial inquiries

Our team of Sales Specialists

Tel.: +45 5537 2095

Email: quotes@insatech.com

How Does a Butterfly Valve Work?

A butterfly valve operates using a rotating disc mounted on a shaft that controls or blocks the flow of a liquid or gas. Because it only needs to rotate 90 degrees, it is considered a “quarter-turn” valve, similar to ball and plug valves.

These valves are popular for their simple design, low weight, and cost-effectiveness. They are used across industries such as oil & gas and marine operations.

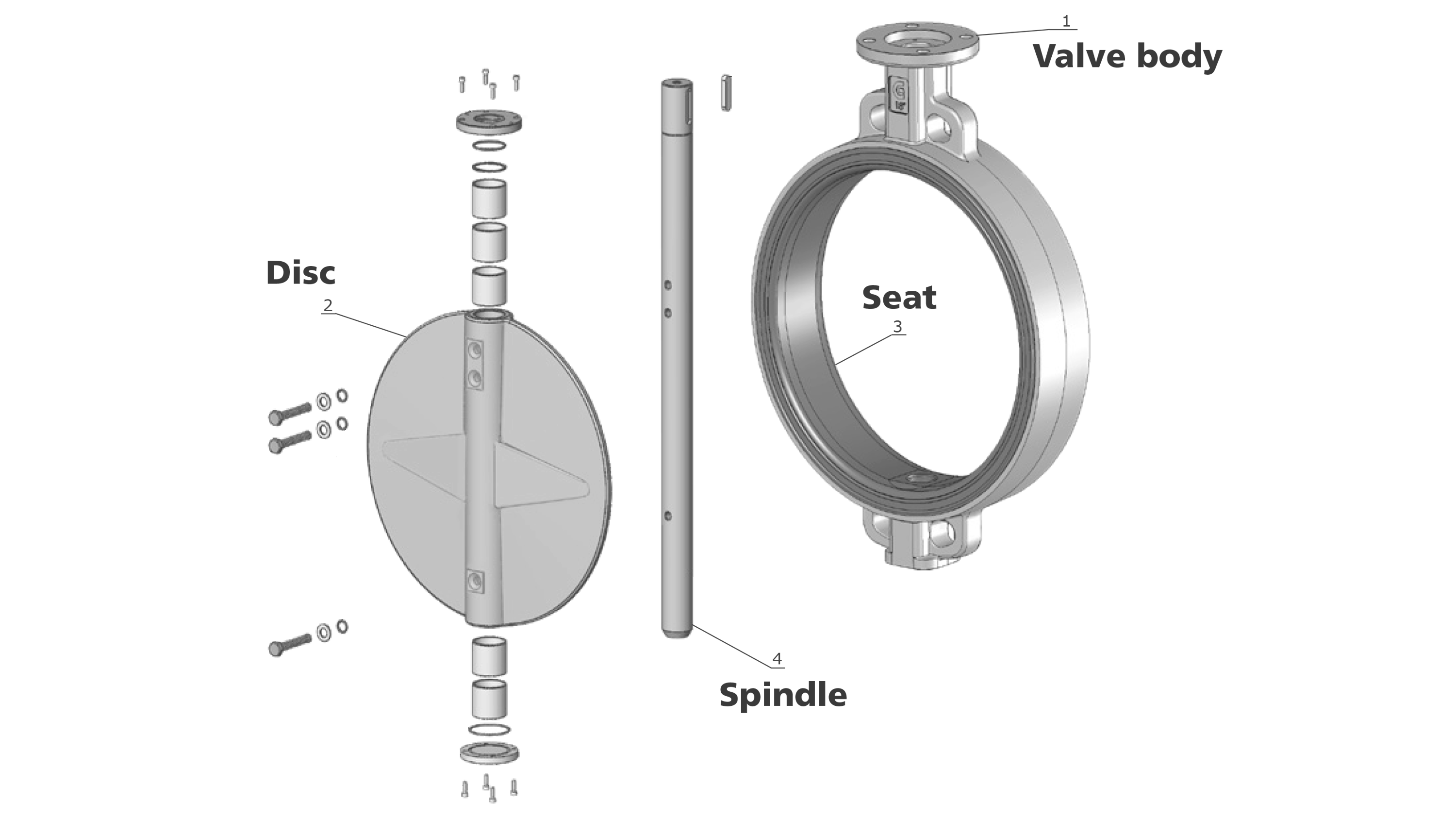

Key Components

- Valve body

- Disc

- Seat

- Shaft

The shaft passes through the body and disc, while the seat and disc work together to seal the flow. Some designs involve friction between the seat and disc, which is why seats are often made of elastomers, though metal-to-metal sealing is also possible.

Why Is It Called a Butterfly Valve?

The name comes from the resemblance of the valve components to a butterfly: the shaft is the body, and the disc represents the wings. When closed, the wings are spread; when open, they are tucked back.

Butterfly valves can be operated manually or automatically, with manual handles or gearboxes, or with actuators for automation.

Types of Butterfly Valves: Centric vs. Eccentric

Butterfly valves are available in four main types:

Centered (Centric)

The shaft is centered within both the valve body and disc. While this allows full 360° movement, constant friction between seat and disc can cause faster wear. Suitable for wastewater, fire protection, and gas delivery systems.

Single Eccentric (Single Offset)

The shaft is offset from the centerline of the disc, reducing friction slightly. Typically used in low-pressure and low-temperature systems.

Double Eccentric (Double Offset)

The shaft is offset both from the center of the disc and the center of the pipe. This design minimizes seat friction during opening and closing, allowing for metal seating and higher temperature use. Common in buried water applications

Triple Eccentric (Triple Offset)

In addition to the double offset, the disc and seat are conical. This eliminates friction until final closure, enabling metal-to-metal sealing. Suitable for steam, high pressure, high temperature, and corrosive or abrasive media.

Below is an animation of how the four types of butterfly valves move.

Wafer

Held between two flanges and secured with bolts. Allows for slight alignment during installation. Requires gaskets or O-rings on both sides.

Lug

Also installed between flanges, but includes threaded holes for bolts. Allows disconnection from one side without affecting the other. Suitable for dead-end service but also supports the pipe load.

Flange

Each side of the valve has a flange with bolt holes (non-threaded). Ideal for large valves or extreme temperature applications. Typically used with gaskets or O-rings.

Manual or Automatic Operation

Like other valve types, butterfly valves are available with both manual and automatic operation options. Manual control is typically achieved using handles or gearboxes, while automatic control is handled via actuators.

Handle Operation

A handle can be used to manually open or close a butterfly valve. This solution is typically suitable for smaller valves, as the required torque for larger valves is often too high to operate manually. One of the main advantages of handles is the ability to shut off the valve quickly.

Gear Operation

For larger butterfly valves, it is often necessary to use a gearbox. The gearing mechanism makes it possible to overcome the torque on the disc, allowing the valve to be closed manually. However, gear operation is slightly slower compared to using a handle.

Actuators

If you want to control the valve automatically, this can be done using actuators. Actuators are typically available in electric, pneumatic (compressed air), or hydraulic (fluid) versions.

You can view our range of actuators here.

Pressure Loss and Flow Turbulence

Typically, the pressure loss through a butterfly valve is minimal. However, since the disc remains within the flow path, some degree of pressure drop is unavoidable. In addition, the disc can create turbulence in the media as it passes through the valve.

Materials

Butterfly valves are available in various material combinations depending on the application. For example, food-grade seat materials may be required in hygienic applications, while highly aggressive media may call for the use of a special alloy. Some materials are better suited to handle high pressure or extreme temperatures.

If you would like assistance in selecting the right valve material and configuration for your application, feel free to contact our valve team.

Maintenance

To ensure the valve remains leak-free, it is important to perform regular maintenance. Butterfly valves are relatively simple in design, which makes them easier to service than many other valve types. Maintenance typically includes replacing the seat and stem seals to maintain proper tightness.