Check valves effectively prevent reverse flow of liquids and gases in industrial pipeline systems. At Insatech, we offer reliable solutions designed to protect your equipment and maintain optimal flow control across a wide range of applications - including high-performance Ghibson check valves.

Check Valve

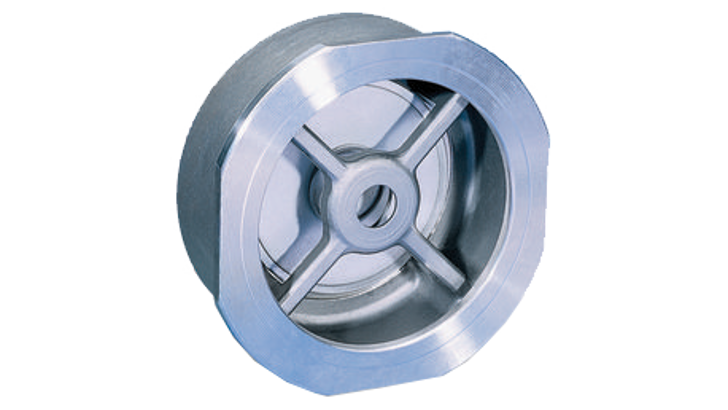

Ghibson - Wafer Check Valve GA015

The Wafer Check Valve GA015 from Ghibson is available in DN 15 to DN 100 - 1/2” to 4”, Pmax 52 bar. Furthermore, you can get it with a house, disc, seat plate, and spring in stainless steel and other materials on request.

Check Valve

Ghibson - Wafer check valve GB 015

Ghibson - Wafer check valve GB 015 is available in DN 15 to DN 100 - 1/2” to 4”, Pmax 52 bar. Moreover, it is small in size, low in weight and can be installed in all positions. Available with house, disc, spring, and top ring in stainless steel.

Check Valve

Ghibson - Wafer check valve GB 023

Ghibson - Wafer check valve GB 023 is available in DN 15 to DN 100 - 1/2” to 4 ”, Pmax 6 bar. Moreover, it has an opening pressure from 20 to 500 mbar. Available with house, disc, and seat in PTFE.

Check Valve

Ghibson - Wafer check valve GN 011

Ghibson - Wafer check valve GN 011 is available in DN 15 to DN 100 - 1/2 ”to 4”, Pmax 52 bar. Moreover, it is small in size, low in weight, and can be installed in all positions. Usable also as vacuum breacker, overpressure and bottom valve. Disc, spring, and seat in stainless steel and house in galvanized steel.

Check Valve

Ghibson - Wafer check valve GN 015

Ghibson - Wafer check valve GN 015 is available in DN 15 to DN 100 - 1/2 ”to 4”, Pmax 52 bar. Moreover, it is small in size, low in weight, and can be installed in all positions. Usable also as vacuum breacker, overpressure and bottom valve. House, disc, spring, and seat in stainless steel.

Check Valve

Ghibson - Wafer check valve GN 091

Ghibson - Wafer check valve GN 091 is available in DN 15 to DN 100 - 1/2 ”to 4”, Pmax 52 bar. Moreover, it is small in size, low in weight, and can be installed in all positions. Usable also as vacuum breacker, overpressure and bottom valve. House, disc, spring, and seat in hastelloy.

Previously known as GN115.

Check Valve

Ghibson - Wafer check valve GN 095

Ghibson - Wafer check valve GN 095 is available in DN 15 to DN 100 - 1/2 ”to 4”, Pmax 52 bar. Moreover, it is small in size, low in weight, and can be installed in all positions. Usable also as vacuum breacker, overpressure and bottom valve. House, disc, spring, and seat in super duplex.

Check Valve

Ghibson - Wafer check valve GT 011

Ghibson - Wafer check valve GT 011 is available in DN 15 to DN 100 - 1/2 "to 4", Pmax 160 bar. Moreover, it is small in size, low in weight, and can be installed in all positions. Usable also as vacuum breacker, overpressure and bottom valve. Available with disc, spring, and seat in stainless steel and house in galvanized steel.

Check Valve

Ghibson - Wafer check valve GT 015

Ghibson - Wafer check valve GT 015 is available in DN 15 to DN 100 - 1/2 "to 4", Pmax 160 bar. Moreover, it is small in size, low in weight, and can be installed in all positions. Usable also as vacuum breacker, overpressure and bottom valve. Available with house, disc, spring, and seat in stainless steel.

No results found

Check Valves for Industrial and Marine Applications

Whether you need a wafer check valve with or without a swing-type disc, we supply both disc and swing types from trusted brands such as Ghibson:

- Disc check valves can be installed in all orientations (horizontal or vertical)

- Swing check valves can be installed horizontally or vertically depending on model

The difference lies in their internal mechanism. Choosing the right design depends on your application and installation requirements.

Product Highlights

- Compact design and lightweight construction

- Designed for pressures up to 160 bar

- Suitable as vacuum breakers, for overpressure protection, or as a Non-return valve

- Available in a wide selection of materials including stainless steel, Hastelloy, and Super Duplex

- Includes certified Ghibson check valve options for industrial and marine applications

What Is a Check Valve?

A check valve is a type of valve that prevents liquid or gas from flowing backward in a system. It protects critical equipment and ensures unidirectional flow, preventing potential damage to components such as pumps, valves, and pipelines.

Check valves are widely used in industrial systems - including pump stations, pipelines, and ventilation systems - to ensure reliable and efficient operation.

Types of Check Valves

Swing Check Valve (Flap Type)

Uses a hinged flap that swings open when flow moves in the correct direction. If flow reverses, the flap quickly closes to stop backflow. Ideal for use in pipelines and pump systems where rapid closure is essential to protect equipment.

Disc Check Valve (Spring-Loaded Type)

This valve features a disc pressed against the seat by a spring. When flow occurs in the correct direction, the disc lifts to allow passage. When flow stops or reverses, the spring pushes the disc back to seal the valve. This type is compact, reliable, and effective at preventing reverse flow.

Applications of Check Valves

Check valves are critical components in various systems, including:

- Pipelines: Prevent reverse flow that could lead to pressure build-up or equipment damage

- Pump systems: Protect pumps from backflow that could harm motors or disrupt pressure balance

- Ventilation systems: Stop air from flowing back into ductwork, which could affect air quality and efficiency

- Marine systems: Robust marine check valves designed to perform under challenging sea conditions

How Does a Check Valve Work?

A check valve operates automatically, closing when liquid or gas attempts to flow in the wrong direction. It seals tightly to prevent backflow and protect downstream equipment. Some check valves are purely mechanical, while others allow for controlled closing based on specific pressure or flow conditions.

Benefits of Using Check Valves

- Protects equipment: Prevents reverse flow damage to pumps, motors, and valves - extending equipment life and reducing downtime

- Maintains system integrity: Helps prevent pressure spikes and backflow failures in pipelines and process systems

- Supports safe and stable operation: Especially critical in high-pressure and sensitive installations

- Available in marine-grade configurations: Including Ghibson check valves and heavy-duty marine check valve models

Get in Touch with Our Experts

For commercial inquiries

Our team of Sales Specialists

Tel.: +45 5537 2095

Email: quotes@insatech.com